what is the oil seal and what is the difference between TC oil seal ,TB oil seal ,TA oil seal ?

what is the oil seal and what is the difference between TC oil seal ,TB oil seal ,TA oil seal ?

The machine produce oil seal

- TC is the representation method for new national standards.

Japan, Taiwan, and other places. FB is the representation method of the old national standard, with the same structure and content. Similarly, many European standards use AS to represent TC and FB oil seals. The standards for FB and FC are GB10708.3-189. TC is the representation method for new national standards, Japan, Taiwan, and other places. TC oil seal is a mechanical component used to seal oil (oil is the most common liquid substance in transmission systems, also commonly referred to as a general liquid substance).

(1). FB is the representation method of the old national standard, with the same structure and content.

(2). Many internal standards in Europe use AS oil seal to represent TC and FB oil seals.

Oil seals are widely used in various industrial fields, especially in mechanical equipment such as hydraulic systems, engines, pumps, gearboxes, transmission devices, and automobiles. They help maintain the normal operation of mechanical equipment, extend the service life of the equipment, reduce maintenance costs, and ensure the efficient performance of the equipment.

The design and selection of oil seals must consider multiple factors, including working environment, liquid type, temperature range, pressure requirements, speed requirements, etc. Different types of oil seals are suitable for different application scenarios. Common types of oil seals include rotary shaft seals, piston seals, static seals, etc. Oil seals usually have inner and outer lips, with the inner lip tightly against the rotating shaft and the outer lip tightly against the fixed components. This creates a sealing effect due to the friction between the inner and outer lips during the operation of the rotating shaft.

In summary, oil seals play a crucial role in fields such as engineering machinery, automobiles, and industrial equipment, ensuring the normal operation of mechanical equipment, preventing liquid leakage and external impurities from entering, thereby ensuring the stability, safety, and efficient performance of the equipment.

1. Oil seal representation method

Common representation methods:

Oil seal type - inner diameter - outer diameter - height - material

For example, TC40 * 62 * 12-NBR represents a double lip inner skeleton oil seal with an inner diameter of 40, an outer diameter of 62, a thickness of 12, and a material of nitrile rubbe

2.Material of oil seal

Nitrile rubber (NBR): wear-resistant, oil resistant (cannot be used in polar media), temperature resistance: -40~120 ℃.

Hydrogenated nitrile rubber (HNBR): Wear resistance, oil resistance, aging resistance, temperature resistance: -40~200 ℃ (stronger than NBR temperature resistance).

Fluorine adhesive (FKM): acid and alkali resistant, oil resistant (all oil resistant), temperature resistant: -20~300 ℃ (oil resistance is better than the above two).

Polyurethane rubber (TPU): Wear resistance, aging resistance, temperature resistance: -20~250 ℃ (excellent aging resistance).

Silicone rubber (PMQ): heat resistant, cold resistant, small compression set, low mechanical strength, temperature resistance: -60~250 ℃ (excellent temperature resistance).

Polytetrafluoroethylene (PTFE): Good chemical stability, resistance to various media such as acid and alkali, oil, wear resistance, high temperature resistance, high mechanical strength, and good self-lubrication.

Generally speaking, the materials commonly used for skeleton oil seals are nitrile rubber, fluororubber, silicone rubber, and polytetrafluoroethylene. Due to its good self-lubrication, especially when added with bronze, they have better effects, and are all used to make retaining rings, Gly rings, and Stuart seals

Distinguish the model of the skeleton oil seal

The C-type skeleton oil seal can be divided into five types: SC type, TC type, VC type, KC type, and DC type. They are single lip inner skeleton oil seal, double lip inner skeleton oil seal, single lip spring free inner skeleton oil seal, double lip spring free inner skeleton oil seal, and double lip spring free inner skeleton oil seal. (We recommend you pay attention to the "Mechanical Engineer" official account to grasp dry goods knowledge and industry information at the first time)

The G-type skeleton oil seal has a threaded shape on the outside, similar to the C-type. It is only modified to have a threaded shape on the outside in terms of technology, similar to the function of an O-ring, which not only strengthens the sealing effect but also fixes the oil seal without loosening.

The B-type skeleton oil seal has adhesive on the inner side of the skeleton or there is no adhesive on both sides of the skeleton. The absence of adhesive will improve heat dissipation performance.

The A-type skeleton oil seal is a prefabricated oil seal with a relatively complex structure compared to the above three types, characterized by better and superior pressure performance.

3.They all have different forms of oil seals and are referred to as general purpose oil seals as follows:

4.Sealing Principle and Application of Oil Seal

The skeleton oil seal is divided into three parts: self tightening spring, sealing body, and strengthening skeleton.The sealing principle of skeleton oil seal: Due to the presence of an oil film controlled by the oil seal blade between the oil seal and the shaft, this oil film has fluid lubrication characteristics.Sealing principle analysis: Under the action of the skeleton oil seal, the stiffness of the oil film precisely forms a crescent surface at the contact end between the oil film and the air, preventing the leakage of the working medium and achieving the sealing of the rotating shaft.The sealing ability of an oil seal depends on the thickness of the oil film on the sealing surface. If the thickness is too large, the oil seal will leak; If the thickness is too small, dry friction may occur, causing wear on the oil seal and shaft; There is no oil film between the sealing lip and the shaft, which can easily cause heating and wear. Therefore, during installation, it is necessary to apply some oil to the sealing ring while ensuring that the skeleton oil seal is perpendicular to the shaft centerline. If it is not perpendicular, the sealing lip of the oil seal will drain the lubricating oil from the shaft and cause excessive wear of the sealing lip. During operation, the lubricant inside the shell slightly seeps out to form at the sealing surface.

5. The function of skeleton oil seal

Generally, the components that need lubrication in the transmission components are isolated from the output components to prevent lubricating oil leakage. It is commonly used for rotating shafts and is a type of rotating shaft lip seal. The skeleton is like the steel bars inside the concrete component, playing a strengthening role and allowing the oil seal to maintain its shape and tension. According to the type of skeleton, it can be divided into inner skeleton oil seal, outer skeleton oil seal, and inner and outer exposed skeleton oil seal. The skeleton oil seal is made of high-quality nitrile rubber and steel plate, with stable quality and long service life.

1. Prevent mud, dust, moisture, etc. from entering the bearing from outside;

2. Limit the leakage of lubricating oil in the bearings. The requirement for oil seals is that the dimensions (inner diameter, outer diameter, and thickness) should comply with regulations; Require appropriate elasticity to properly clamp the shaft and provide a sealing effect; It should be heat-resistant, wear-resistant, strong, resistant to media (such as oil or water), and have a long service life.

6.Selection of oil seals

The selection of oil seals should be based on the sealing medium and working conditions. The sealing medium needs to choose the material of the oil seal, and the working conditions mainly consider the use pressure, working line speed, and working temperature range.

When selecting the material for oil seals, it is necessary to consider the compatibility of the material with the working medium, adaptability to the working temperature range, and the ability of the lip to follow the high-speed rotation of the rotating shaft. When working with a general oil seal, the temperature of its lip is 20~50 ℃ higher than the temperature of the working medium. Attention should be paid when selecting oil seal materials.

The service pressure of ordinary oil seals generally does not exceed 0.05MPa. When the working pressure exceeds this value, a pressure resistant oil seal should be selected. (We recommend you pay attention to the "Mechanical Engineer" official account to grasp dry goods knowledge and industry information at the first time)

Under the same diameter condition, oil seals made of different materials have different abilities to adapt to the linear speed of shaft rotation. The linear speed range used for oil seals is generally less than 15m/s.

The working range of the oil seal is related to the material used: -40~120 ℃ for nitrile rubber (NBR), -30~180 ℃ for acrylic rubber (ACM), and -25~300 ℃ for fluororubber (FPM).

7.Design requirements for corresponding shafts and cavities

Shaft design:

1. Surface roughness, due to differences in shaft speed and oil volume, can generally affect oil seal leakage and wear if the roughness of the shaft is too large or too small. The allowable range of surface roughness of the shaft is Rz1.0~5.0 μ M; Ra0.2~0.8 μ M. Take 2.5-1.6 oil seals for the rotating shaft μ MRz.

2. Hardness, the surface hardness of the rotating shaft is generally taken as ≥ 35HRC. When the medium is dirty, there are pollutants from the outside, or the shaft surface speed is>12m/s, the surface hardness of the shaft should be above 55HRC, and the depth of the quenching layer on the shaft surface should be>0.2mm.

3. The recommended chamfer of the shaft is between 15 ° and 30 °, in order to ensure that the oil seal is truly installed without damaging the lip of the oil seal.

4. The processing of the shaft and the correct processing of the shaft are the decisive factors to ensure the normal operation of the sealing system. The suitable method for processing the oil seal shaft is to provide precision grinding horizontally and to polish it with emery paper. Unsuitable processing methods are precision machining, ultra precision machining, rolling machining, and diamond sandpaper polishing on a lathe (sandpaper is polished by axial movement).

5. The material of the shaft is mainly ordinary carbon structural steel, such as C35 and C45, as well as cast iron, ceramics, and resin plastic. However, the sealing of the oil seal in the latter three materials of the shaft has defects.

1. The recommended installation chamfer value is 15 °~30 °.

2. The material of the chamber is steel or cast iron, and it is acceptable to use an oil seal with a rubber or metal outer circumference. Generally, light alloys and resins have a high coefficient of thermal expansion, making it suitable to use oil seals with rubber around them.

3. Unsuitable cavity structures, such as those that are processed by stamping, those that are installed with threaded combinations, and those with split cavities.

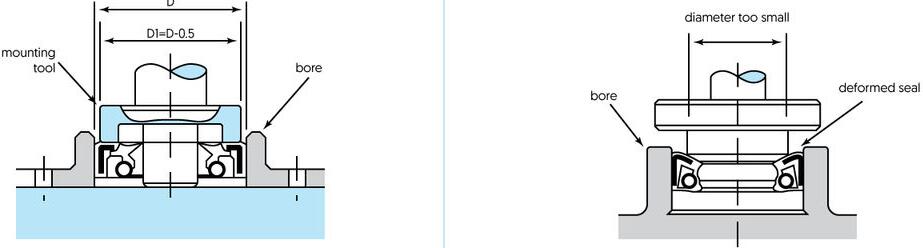

8.Installation of oil seal

1.Before installation, the oil seal should be appropriately coated with lithium ester containing molybdenum disulfide between the lips to prevent dry wear on the lips when the shaft starts instantly, affecting the interference of the lips. Assembly should be carried out as soon as possible. If the oil seal seat is not installed immediately, it is recommended to cover it with a cloth to prevent foreign objects from adhering to the oil seal. The hands or tools used to apply lithium grease must be clean. (We recommend you pay attention to the "Mechanical Engineer" official account to grasp dry goods knowledge and industry information at the first time)

2. The oil seal should be installed flat without tilting. It is recommended to use hydraulic equipment or sleeve tools for installation. The pressure should not be too high, and the speed should be uniform and slow.

3. When installing the oil seal, oil or lubricating oil should be applied and the shaft end and shoulder should be rounded off.

4.When installing the oil seal, be sure to face the lip end towards the side of the sealed oil, and avoid reverse assembly.

5. When installing the oil seal into the seat hole, special tools should be used to push it in to prevent deviation.

6. Various measures should be taken to prevent lip damage at the threads, keyways, splines, etc. where the oil seal lip passes through, and special tools should be used for assembly.

7. When disassembling the oil seal, avoid damaging the surface inside the cavity and the surface of the shaft.

8. The used oil seal, even if it has a good appearance, cannot be used anymore and must be replaced with a new one.

9. When there are scratches or rust on the surface of the shaft, it must be repaired.

When installing a new oil seal, in order to keep it away from the old lip contact area, a gasket should be used to avoid the original friction marks.

oil seal direction of installation

9.The size table for TC oil seal ,SC oil seal , A oil seal , AS oil seal .

| ID | OD | H | Material | ID | OD | H |

| 4 | 17 | 7 | NBR/FKM | 42 | 53 | 8 |

| 4 | 18 | 7 | NBR/FKM | 42 | 54 | 7 |

| 4.5 | 15 | 5 | NBR/FKM | 42 | 54.5 | 6 |

| 4.5 | 16 | 7 | NBR/FKM | 42 | 55 | 6 |

| 4.5 | 17 | 7 | NBR/FKM | 42 | 55 | 7 |

| 4.5 | 18 | 7 | NBR/FKM | 42 | 55 | 8 |

| 4.8 | 17 | 7 | NBR/FKM | 42 | 55 | 9 |

| 4.8 | 25 | 5.5 | NBR/FKM | 42 | 55 | 10 |

| 5 | 12 | 8 | NBR/FKM | 42 | 55 | 12 |

| 5 | 15 | 5 | NBR/FKM | 42 | 56 | 7 |

| 5 | 15 | 6 | NBR/FKM | 42 | 56 | 8 |

| 5 | 16 | 6 | NBR/FKM | 42 | 56 | 9 |

| 5 | 16 | 8 | NBR/FKM | 42 | 56 | 10 |

| 5 | 17 | 6 | NBR/FKM | 42 | 57 | 7 |

| 5 | 17 | 7 | NBR/FKM | 42 | 57 | 10 |

| 5 | 18 | 6 | NBR/FKM | 42 | 58 | 7 |

| 5 | 18 | 7 | NBR/FKM | 42 | 58 | 8 |

| 5 | 19 | 7 | NBR/FKM | 42 | 58 | 10 |

| 5 | 22 | 7 | NBR/FKM | 42 | 58 | 12 |

| 5.2 | 14 | 4 | NBR/FKM | 42 | 59 | 10 |

| 5.5 | 16 | 8 | NBR/FKM | 42 | 60 | 6 |

| 6 | 12 | 8 | NBR/FKM | 42 | 60 | 7 |

| 6 | 15 | 4 | NBR/FKM | 42 | 60 | 8 |

| 6 | 15 | 7 | NBR/FKM | 42 | 60 | 9 |

| 6 | 15 | 4S | NBR/FKM | 42 | 60 | 10 |

| 6 | 16 | 5 | NBR/FKM | 42 | 60 | 12 |

| 6 | 16 | 7 | NBR/FKM | 42 | 62 | 7 |

| 6 | 17 | 7 | NBR/FKM | 42 | 62 | 8 |

| 6 | 18 | 6 | NBR/FKM | 42 | 62 | 9 |

| 6 | 18 | 7 | NBR/FKM | 42 | 62 | 10 |

| 6 | 19 | 7 | NBR/FKM | 42 | 62 | 12 |

| 6 | 20 | 5.5 | NBR/FKM | 42 | 62 | 17Z |

| 6 | 22 | 7 | NBR/FKM | 42 | 63 | 7 |

| 6 | 22 | 8 | NBR/FKM | 42 | 64 | 7 |

| 6 | 25 | 8 | NBR/FKM | 42 | 64 | 8 |

| 6 | 26 | 7 | NBR/FKM | 42 | 64 | 9 |

| 6 | 34 | 5.5 | NBR/FKM | 42 | 64 | 10 |

| 6 | 34 | 7 | NBR/FKM | 42 | 64 | 12 |

| 6 | 35 | 7 | NBR/FKM | 42 | 65 | 7 |

| 6.5 | 14.5 | 7 | NBR/FKM | 42 | 65 | 8 |

| 7 | 14 | 4 | NBR/FKM | 42 | 65 | 9 |

| 7 | 15 | 5 | NBR/FKM | 42 | 65 | 10 |

| 7 | 16 | 7 | NBR/FKM | 42 | 65 | 12 |

| 7 | 17 | 5 | NBR/FKM | 42 | 66 | 7 |

| 7 | 17 | 5 | NBR/FKM | 42 | 66 | 8 |

| 7 | 18 | 5 | NBR/FKM | 42 | 66 | 10 |

| 7 | 18 | 7 | NBR/FKM | 42 | 67 | 17.6 |

| 7 | 19 | 5 | NBR/FKM | 42 | 68 | 7 |

| 7 | 19 | 7 | NBR/FKM | 42 | 68 | 8 |

| 7 | 20 | 7 | NBR/FKM | 42 | 68 | 10 |

| 7 | 22 | 6 | NBR/FKM | 42 | 68 | 12 |

| 7 | 22 | 7 | NBR/FKM | 42 | 70 | 8 |

| 7 | 22 | 8 | NBR/FKM | 42 | 70 | 10 |

| 7 | 26.2 | 5.5 | NBR/FKM | 42 | 70 | 12 |

| 7 | 31 | 7 | NBR/FKM | 42 | 72 | 5.12 |

| 8 | 13 | 5 | NBR/FKM | 42 | 72 | 8 |

| 8 | 15 | 4 | NBR/FKM | 42 | 72 | 10 |

| 8 | 15 | 4.5 | NBR/FKM | 42 | 72 | 12 |

| 8 | 15 | 5 | NBR/FKM | 42 | 74 | 10 |

| 8 | 16 | 4 | NBR/FKM | 42 | 75 | 10 |

| 8 | 16 | 5 | NBR/FKM | 42 | 75 | 12 |

| 8 | 16 | 6 | NBR/FKM | 42 | 76 | 8 |

| 8 | 16 | 7 | NBR/FKM | 42 | 76 | 10 |

| 8 | 16 | 8 | NBR/FKM | 42 | 76 | 12 |

| 8 | 17 | 7 | NBR/FKM | 42 | 78 | 9.5 |

| 8 | 18 | 4 | NBR/FKM | 42 | 78 | 10 |

| 8 | 18 | 5 | NBR/FKM | 42 | 80 | 8 |

| 8 | 18 | 6 | NBR/FKM | 42 | 80 | 10 |

| 8 | 18 | 7 | NBR/FKM | 42 | 85 | 8 |

| 8 | 18 | 8 | NBR/FKM | 42.05 | 63.05 | 12.7 |

| 8 | 19 | 7 | NBR/FKM | 42.5 | 54.5 | 6 |

| 8 | 20 | 7 | NBR/FKM | 43 | 50 | 7 |

| 8 | 21 | 6 | NBR/FKM | 43 | 55 | 6 |

| 8 | 21.5 | 10 | NBR/FKM | 43 | 55 | 7 |

| 8 | 22 | 4 | NBR/FKM | 43 | 55 | 8 |

| 8 | 22 | 6 | NBR/FKM | 43 | 55 | 9 |

| 8 | 22 | 7 | NBR/FKM | 43 | 55 | 11 |

| 8 | 22 | 8 | NBR/FKM | 43 | 56 | 8 |

| 8 | 22 | 10 | NBR/FKM | 43 | 57 | 11 |

| 8 | 23 | 5 | NBR/FKM | 43 | 58 | 7 |

| 8 | 23 | 7 | NBR/FKM | 43 | 58 | 8 |

| 8 | 24 | 7 | NBR/FKM | 43 | 58 | 11 |

| 8 | 25 | 7 | NBR/FKM | 43 | 60 | 7 |

| 8 | 25 | 8 | NBR/FKM | 43 | 60 | 10 |

| 8 | 25 | 9 | NBR/FKM | 43 | 62 | 8 |

| 8 | 26 | 7 | NBR/FKM | 43 | 62 | 12 |

| 8 | 28 | 5 | NBR/FKM | 43 | 63 | 10 |

| 8 | 28 | 7 | NBR/FKM | 43 | 65 | 8 |

| 8 | 30 | 6 | NBR/FKM | 43 | 65 | 10 |

| 8 | 30 | 7 | NBR/FKM | 43 | 66 | 10 |

| 8 | 34 | 8 | NBR/FKM | 43 | 77 | 12.5 |

| 9 | 15 | 7 | NBR/FKM | 44 | 54 | 4.5 |

| 9 | 17 | 4 | NBR/FKM | 44 | 54 | 7 |

| 9 | 17 | 6 | NBR/FKM | 44 | 55 | 5.5 |

| 9 | 18 | 7 | NBR/FKM | 44 | 55 | 7 |

| 9 | 19 | 5 | NBR/FKM | 44 | 56 | 10 |

| 9 | 19 | 7 | NBR/FKM | 44 | 57 | 9 |

| 9 | 20 | 5 | NBR/FKM | 44 | 58 | 4 |

| 9 | 20 | 6 | NBR/FKM | 44 | 58 | 8 |

| 9 | 20 | 7 | NBR/FKM | 44 | 59 | 8 |

| 9 | 21 | 5 | NBR/FKM | 44 | 60 | 7 |

| 9 | 22 | 7 | NBR/FKM | 44 | 60 | 8 |

| 9 | 24 | 7 | NBR/FKM | 44 | 60 | 10 |

| 9 | 25 | 7 | NBR/FKM | 44 | 62 | 7 |

| 9 | 26 | 7 | NBR/FKM | 44 | 62 | 8 |

| 9 | 29 | 7 | NBR/FKM | 44 | 62 | 10 |

| 9 | 30 | 7 | NBR/FKM | 44 | 62 | 12 |

| 9.2 | 17.5 | 8 | NBR/FKM | 44 | 63.5 | 10 |

| 9.6 | 17.5 | 7 | NBR/FKM | 44 | 64 | 9 |

| 10 | 15 | 4 | NBR/FKM | 44 | 65 | 8 |

| 10 | 16 | 5 | NBR/FKM | 44 | 65 | 10 |

| 10 | 16 | 7 | NBR/FKM | 44 | 65 | 11 |

| 10 | 17 | 4 | NBR/FKM | 44 | 67 | 10 |

| 10 | 17 | 5 | NBR/FKM | 44 | 68 | 8 |

| 10 | 17 | 7 | NBR/FKM | 44 | 68 | 13 |

| 10 | 17.5 | 7 | NBR/FKM | 44 | 70 | 12 |

| 10 | 18 | 4 | NBR/FKM | 44 | 72 | 8 |

| 10 | 18 | 5 | NBR/FKM | 44 | 72 | 10 |

| 10 | 18 | 6 | NBR/FKM | 44 | 76 | 9.5 |

| 10 | 18 | 7 | NBR/FKM | 44 | 88 | 8 |

| 10 | 18 | 8 | NBR/FKM | 44.45 | 57.15 | 9.52 |

| 10 | 19 | 4 | NBR/FKM | 44.5 | 62 | 10 |

| 10 | 19 | 5 | NBR/FKM | 45 | 50 | 8 |

| 10 | 19 | 6 | NBR/FKM | 45 | 50 | 10 |

| 10 | 19 | 7 | NBR/FKM | 45 | 52 | 8 |

| 10 | 19 | 10 | NBR/FKM | 45 | 54 | 4.5 |

| 10 | 20 | 4 | NBR/FKM | 45 | 55 | 6 |

| 10 | 20 | 4.5 | NBR/FKM | 45 | 55 | 7 |

| 10 | 20 | 5 | NBR/FKM | 45 | 55 | 8 |

| 10 | 20 | 6 | NBR/FKM | 45 | 55 | 10 |

| 10 | 20 | 7 | NBR/FKM | 45 | 55 | 12 |

| 10 | 20 | 9 | NBR/FKM | 45 | 56 | 7 |

| 10 | 20 | 9.5 | NBR/FKM | 45 | 56 | 8 |

| 10 | 20.1 | 5 | NBR/FKM | 45 | 56 | 10 |

| 10 | 21 | 4 | NBR/FKM | 45 | 57 | 8 |

| 10 | 21 | 5 | NBR/FKM | 45 | 57 | 9 |

| 10 | 21 | 6 | NBR/FKM | 45 | 57 | 11 |

| 10 | 21 | 7 | NBR/FKM | 45 | 58 | 4 |

| 10 | 21 | 10.5 | NBR/FKM | 45 | 58 | 7 |

| 10 | 22 | 5 | NBR/FKM | 45 | 58 | 8 |

| 10 | 22 | 6 | NBR/FKM | 45 | 58 | 9 |

| 10 | 22 | 7 | NBR/FKM | 45 | 58 | 10 |

| 10 | 22 | 8 | NBR/FKM | 45 | 58 | 12 |

| 10 | 23 | 7 | NBR/FKM | 45 | 59 | 7 |

| 10 | 23 | 8 | NBR/FKM | 45 | 59 | 10 |

| 10 | 23 | 9 | NBR/FKM | 45 | 60 | 7 |

| 10 | 23.5 | 7 | NBR/FKM | 45 | 60 | 8 |

| 10 | 24 | 4 | NBR/FKM | 45 | 60 | 9 |

| 10 | 24 | 5 | NBR/FKM | 45 | 60 | 10 |

| 10 | 24 | 6 | NBR/FKM | 45 | 60 | 12 |

| 10 | 24 | 7 | NBR/FKM | 45 | 62 | 7 |

| 10 | 24 | 8 | NBR/FKM | 45 | 62 | 8 |

| 10 | 25 | 5 | NBR/FKM | 45 | 62 | 9 |

| 10 | 25 | 7 | NBR/FKM | 45 | 62 | 10 |

| 10 | 25 | 8 | NBR/FKM | 45 | 62 | 12 |

| 10 | 25 | 10 | NBR/FKM | 45 | 63 | 7 |

| 10 | 26 | 5 | NBR/FKM | 45 | 63.5 | 9.5 |

| 10 | 26 | 6 | NBR/FKM | 45 | 63.5 | 12 |

| 10 | 26 | 7 | NBR/FKM | 45 | 64 | 7 |

| 10 | 26 | 8 | NBR/FKM | 45 | 64 | 8 |

| 10 | 27 | 6 | NBR/FKM | 45 | 64 | 10 |

| 10 | 28 | 7 | NBR/FKM | 45 | 64 | 14.5 |

| 10 | 28 | 10 | NBR/FKM | 45 | 65 | 5 |

| 10 | 28 | 13.4 | NBR/FKM | 45 | 65 | 7 |

| 10 | 29 | 7 | NBR/FKM | 45 | 65 | 8 |

| 10 | 30 | 7 | NBR/FKM | 45 | 65 | 9 |

| 10 | 30 | 10 | NBR/FKM | 45 | 65 | 10 |

| 10 | 30 | 12 | NBR/FKM | 45 | 65 | 11 |

| 10 | 31 | 7 | NBR/FKM | 45 | 65 | 12 |

| 10 | 31 | 13.5 | NBR/FKM | 45 | 65 | 14 |

| 10 | 32 | 7 | NBR/FKM | 45 | 65.5 | 7 |

| 10 | 32 | 10 | NBR/FKM | 45 | 66 | 7 |

| 10 | 35 | 4 | NBR/FKM | 45 | 66 | 10 |

| 10 | 35 | 8 | NBR/FKM | 45 | 67 | 8 |

| 11 | 17 | 4 | NBR/FKM | 45 | 68 | 8 |

| 11 | 17 | 4.5 | NBR/FKM | 45 | 68 | 9 |

| 11 | 17 | 5 | NBR/FKM | 45 | 68 | 10 |

| 11 | 17.2 | 4 | NBR/FKM | 45 | 68 | 12 |

| 11 | 17.65 | 5/6.5 | NBR/FKM | 45 | 70 | 5 |

| 11 | 18 | 4 | NBR/FKM | 45 | 70 | 8 |

| 11 | 18 | 5 | NBR/FKM | 45 | 70 | 8.5 |

| 11 | 19 | 4.5 | NBR/FKM | 45 | 70 | 10 |

| 11 | 20 | 7 | NBR/FKM | 45 | 70 | 12 |

| 11 | 21 | 7 | NBR/FKM | 45 | 72 | 7 |

| 11 | 22 | 7 | NBR/FKM | 45 | 72 | 8 |

| 11 | 22 | 8 | NBR/FKM | 45 | 72 | 8.5 |

| 11 | 23 | 7 | NBR/FKM | 45 | 72 | 10 |

| 11 | 24 | 6 | NBR/FKM | 45 | 72 | 12 |

| 11 | 24 | 7 | NBR/FKM | 45 | 72 | 15 |

| 11 | 25 | 7 | NBR/FKM | 45 | 73 | 10 |

| 11 | 25 | 9 | NBR/FKM | 45 | 75 | 7 |

| 11 | 26 | 4 | NBR/FKM | 45 | 75 | 8 |

| 11 | 26 | 7 | NBR/FKM | 45 | 75 | 10 |

| 11 | 28 | 7 | NBR/FKM | 45 | 75 | 12 |

| 11 | 29 | 7 | NBR/FKM | 45 | 76 | 10 |

| 11 | 30 | 5 | NBR/FKM | 45 | 76 | 12 |

| 11 | 30 | 7 | NBR/FKM | 45 | 78 | 8 |

| 11 | 30 | 10 | NBR/FKM | 45 | 78 | 12 |

| 11.6 | 24 | 10 | NBR/FKM | 45 | 80 | 8 |

| 12 | 18 | 5 | NBR/FKM | 45 | 80 | 10 |

| 12 | 18 | 6 | NBR/FKM | 45 | 80 | 12 |

| 12 | 19 | 5 | NBR/FKM | 45 | 81 | 10 |

| 12 | 19 | 7 | NBR/FKM | 45 | 82 | 12 |

| 12 | 19 | 8 | NBR/FKM | 45 | 85 | 10 |

| 12 | 20 | 4 | NBR/FKM | 45 | 85 | 12 |

| 12 | 20 | 5 | NBR/FKM | 45 | 90 | 10 |

| 12 | 20 | 5.5 | NBR/FKM | 45 | 93 | 5.8 |

| 12 | 20 | 6 | NBR/FKM | 45 | 93 | 8.5 |

| 12 | 20 | 7 | NBR/FKM | 45 | 100 | 10 |

| 12 | 21 | 4 | NBR/FKM | 46 | 58 | 5 |

| 12 | 21 | 5 | NBR/FKM | 46 | 58 | 6 |

| 12 | 21 | 7 | NBR/FKM | 46 | 58 | 7 |

| 12 | 21.5 | 5 | NBR/FKM | 46 | 60 | 10 |

| 12 | 21.5 | 6 | NBR/FKM | 46 | 62 | 8 |

| 12 | 21.5 | 7 | NBR/FKM | 46 | 63 | 7 |

| 12 | 22 | 4 | NBR/FKM | 46 | 68 | 8 |

| 12 | 22 | 5 | NBR/FKM | 46 | 70 | 8 |

| 12 | 22 | 6 | NBR/FKM | 46 | 78 | 10 |

| 12 | 22 | 7 | NBR/FKM | 47 | 56 | 7 |

| 12 | 22 | 8 | NBR/FKM | 47 | 57 | 7 |

| 12 | 22 | 9 | NBR/FKM | 47 | 57 | 11 |

| 12 | 22 | 10 | NBR/FKM | 47 | 58 | 7 |

| 12 | 22.5 | 5 | NBR/FKM | 47 | 60 | 7 |

| 12 | 23 | 7 | NBR/FKM | 47 | 62 | 6 |

| 12 | 23 | 8 | NBR/FKM | 47 | 62 | 7 |

| 12 | 23 | 10 | NBR/FKM | 47 | 62 | 8 |

| 12 | 23.5 | 7 | NBR/FKM | 47 | 65 | 8 |

| 12 | 24 | 4 | NBR/FKM | 47 | 65 | 10 |

| 12 | 24 | 5 | NBR/FKM | 47 | 68 | 8 |

| 12 | 24 | 6 | NBR/FKM | 47 | 68 | 10 |

| 12 | 24 | 7 | NBR/FKM | 47 | 70 | 8 |

| 12 | 25 | 4.5 | NBR/FKM | 47 | 70 | 9 |

| 12 | 25 | 5 | NBR/FKM | 47 | 70 | 10 |

| 12 | 25 | 6 | NBR/FKM | 47 | 70 | 12 |

| 12 | 25 | 7 | NBR/FKM | 47 | 71 | 10 |

| 12 | 25 | 8 | NBR/FKM | 47 | 72 | 8 |

| 12 | 25 | 10 | NBR/FKM | 47 | 72 | 12 |

| 12 | 25.5 | 7 | NBR/FKM | 47 | 74 | 16.7 |

| 12 | 26 | 5 | NBR/FKM | 47 | 79.5 | 12.7 |

| 12 | 26 | 7 | NBR/FKM | 47 | 80 | 10 |

| 12 | 26 | 8 | NBR/FKM | 47 | 80 | 12 |

| 12 | 27 | 7 | NBR/FKM | 47 | 84 | 10 |

| 12 | 28 | 5 | NBR/FKM | 47 | 84 | 12 |

| 12 | 28 | 6 | NBR/FKM | 47 | 90 | 12 |

| 12 | 28 | 7 | NBR/FKM | 47.5 | 70.5 | 9 |

| 12 | 28 | 8 | NBR/FKM | 47.5 | 70.65 | 9 |

| 12 | 28.5 | 5 | NBR/FKM | 47.5 | 70.7 | 9 |

| 12 | 29 | 7 | NBR/FKM | 47.6 | 70 | 13 |

| 12 | 30 | 7 | NBR/FKM | 47.6 | 79.5 | 12.7 |

| 12 | 30 | 8 | NBR/FKM | 48 | 57 | 7 |

| 12 | 30 | 10 | NBR/FKM | 48 | 58 | 7 |

| 12 | 32 | 5 | NBR/FKM | 48 | 58 | 10 |

| 12 | 32 | 5.5 | NBR/FKM | 48 | 60 | 7 |

| 12 | 32 | 7 | NBR/FKM | 48 | 60 | 8 |

| 12 | 32 | 10 | NBR/FKM | 48 | 60 | 10 |

| 12 | 34 | 7 | NBR/FKM | 48 | 62 | 6 |

| 12 | 35 | 6 | NBR/FKM | 48 | 62 | 7 |

| 12 | 35 | 7 | NBR/FKM | 48 | 62 | 8 |

| 12 | 35 | 10 | NBR/FKM | 48 | 62 | 9 |

| 12 | 37 | 7 | NBR/FKM | 48 | 62 | 10 |

| 12 | 45 | 7 | NBR/FKM | 48 | 62 | 12 |

| 12.5 | 32 | 15 | NBR/FKM | 48 | 62 | 13 |

| 12.5 | 34 | 10 | NBR/FKM | 48 | 63 | 10 |

| 12.5 | 38 | 10 | NBR/FKM | 48 | 63.5 | 10 |

| 12.7 | 28 | 6.7 | NBR/FKM | 48 | 64 | 12 |

| 13 | 20 | 4 | NBR/FKM | 48 | 65 | 7 |

| 13 | 20 | 5 | NBR/FKM | 48 | 65 | 8 |

| 13 | 22 | 5 | NBR/FKM | 48 | 65 | 9 |

| 13 | 22 | 5.5 | NBR/FKM | 48 | 65 | 10 |

| 13 | 22 | 7 | NBR/FKM | 48 | 65 | 12 |

| 13 | 23 | 5 | NBR/FKM | 48 | 66 | 7 |

| 13 | 23 | 7 | NBR/FKM | 48 | 67 | 9 |

| 13 | 24 | 7 | NBR/FKM | 48 | 67 | 10 |

| 13 | 25 | 6 | NBR/FKM | 48 | 68 | 7 |

| 13 | 25 | 7 | NBR/FKM | 48 | 68 | 8 |

| 13 | 25 | 8.5 | NBR/FKM | 48 | 68 | 9 |

| 13 | 26 | 7 | NBR/FKM | 48 | 68 | 10 |

| 13 | 26 | 9 | NBR/FKM | 48 | 68 | 12 |

| 13 | 27 | 7 | NBR/FKM | 48 | 69 | 10 |

| 13 | 28 | 7 | NBR/FKM | 48 | 70 | 7 |

| 13 | 28 | 8 | NBR/FKM | 48 | 70 | 8 |

| 13 | 29 | 9 | NBR/FKM | 48 | 70 | 9 |

| 13 | 30 | 7 | NBR/FKM | 48 | 70 | 10 |

| 13 | 30 | 8 | NBR/FKM | 48 | 70 | 12 |

| 13 | 32 | 7 | NBR/FKM | 48 | 70.5 | 9 |

| 13 | 35 | 7 | NBR/FKM | 48 | 72 | 7 |

| 13.7 | 24 | 5 | NBR/FKM | 48 | 72 | 8 |

| 14 | 20 | 4.5 | NBR/FKM | 48 | 72 | 9 |

| 14 | 20 | 5 | NBR/FKM | 48 | 72 | 10 |

| 14 | 20 | 7 | NBR/FKM | 48 | 72 | 12 |

| 14 | 21 | 4 | NBR/FKM | 48 | 72.5 | 10 |

| 14 | 21 | 7 | NBR/FKM | 48 | 73 | 7 |

| 14 | 22 | 4 | NBR/FKM | 48 | 73 | 10 |

| 14 | 22 | 5 | NBR/FKM | 48 | 74 | 10 |

| 14 | 22 | 5.2 | NBR/FKM | 48 | 74 | 12 |

| 14 | 22 | 5.5 | NBR/FKM | 48 | 75 | 8 |

| 14 | 22 | 7 | NBR/FKM | 48 | 75 | 10 |

| 14 | 23 | 6 | NBR/FKM | 48 | 75 | 12 |

| 14 | 23 | 7 | NBR/FKM | 48 | 76 | 10 |

| 14 | 24 | 5 | NBR/FKM | 48 | 76 | 12 |

| 14 | 24 | 6 | NBR/FKM | 48 | 76.3 | 13 |

| 14 | 24 | 7 | NBR/FKM | 48 | 80 | 8 |

| 14 | 25 | 4 | NBR/FKM | 48 | 80 | 10 |

| 14 | 25 | 5 | NBR/FKM | 48 | 80 | 12 |

| 14 | 25 | 6 | NBR/FKM | 48 | 80 | 14 |

| 14 | 25 | 7 | NBR/FKM | 48 | 80.5 | 13 |

| 14 | 25 | 9 | NBR/FKM | 48 | 82 | 10 |

| 14 | 26 | 6 | NBR/FKM | 48 | 82 | 12 |

| 14 | 26 | 7 | NBR/FKM | 48 | 85 | 10 |

| 14 | 27 | 6 | NBR/FKM | 48 | 90 | 13 |

| 14 | 27 | 7 | NBR/FKM | 48 | 100 | 10 |

| 14 | 27 | 9 | NBR/FKM | 48 | 102 | 10 |

| 14 | 28 | 6 | NBR/FKM | 49 | 56 | 9 |

| 14 | 28 | 7 | NBR/FKM | 49 | 59 | 10 |

| 14 | 28 | 8 | NBR/FKM | 49 | 63 | 9 |

| 14 | 29 | 7 | NBR/FKM | 49 | 65 | 7 |

| 14 | 29 | 10 | NBR/FKM | 49 | 66.8 | 9 |

| 14 | 30 | 7 | NBR/FKM | 49 | 67 | 11 |

| 14 | 30 | 7.5 | NBR/FKM | 49 | 72 | 8 |

| 14 | 30 | 8 | NBR/FKM | 50 | 56 | 7 |

| 14 | 30 | 9 | NBR/FKM | 50 | 58 | 4 |

| 14 | 30 | 10 | NBR/FKM | 50 | 60 | 4 |

| 14 | 31 | 7 | NBR/FKM | 50 | 60 | 6 |

| 14 | 32 | 7 | NBR/FKM | 50 | 60 | 8 |

| 14 | 32 | 8 | NBR/FKM | 50 | 60 | 10 |

| 14 | 32 | 10 | NBR/FKM | 50 | 60 | 12 |

| 14 | 33 | 6 | NBR/FKM | 50 | 62 | 5 |

| 14 | 34 | 7 | NBR/FKM | 50 | 62 | 7 |

| 14 | 35 | 7 | NBR/FKM | 50 | 62 | 8 |

| 14 | 35 | 8 | NBR/FKM | 50 | 62 | 9 |

| 14 | 35 | 10 | NBR/FKM | 50 | 62 | 10 |

| 14 | 36 | 7 | NBR/FKM | 50 | 62 | 12 |

| 14 | 40 | 7 | NBR/FKM | 50 | 63 | 6 |

| 14 | 40 | 10 | NBR/FKM | 50 | 63 | 7 |

| 14 | 42 | 7 | NBR/FKM | 50 | 63 | 8 |

| 14.5 | 25.5 | 7 | NBR/FKM | 50 | 64 | 6.5 |

| 14.8 | 30 | 5 | NBR/FKM | 50 | 64 | 8 |

| 14.8 | 30 | 7 | NBR/FKM | 50 | 64 | 10 |

| 14.8 | 32 | 7.5 | NBR/FKM | 50 | 65 | 7 |

| 15 | 21 | 4 | NBR/FKM | 50 | 65 | 8 |

| 15 | 21 | 5 | NBR/FKM | 50 | 65 | 9 |

| 15 | 22 | 5 | NBR/FKM | 50 | 65 | 10 |

| 15 | 22 | 6 | NBR/FKM | 50 | 65 | 12 |

| 15 | 22 | 7 | NBR/FKM | 50 | 66 | 6 |

| 15 | 23 | 4 | NBR/FKM | 50 | 66 | 8 |

| 15 | 23 | 5 | NBR/FKM | 50 | 66 | 10 |

| 15 | 23 | 7 | NBR/FKM | 50 | 67 | 9 |

| 15 | 24 | 5 | NBR/FKM | 50 | 67 | 10 |

| 15 | 24 | 6 | NBR/FKM | 50 | 67 | 11 |

| 15 | 24 | 7 | NBR/FKM | 50 | 68 | 6 |

| 15 | 25 | 4 | NBR/FKM | 50 | 68 | 7 |

| 15 | 25 | 5 | NBR/FKM | 50 | 68 | 8 |

| 15 | 25 | 6 | NBR/FKM | 50 | 68 | 9 |

| 15 | 25 | 7 | NBR/FKM | 50 | 68 | 10 |

| 15 | 25 | 8 | NBR/FKM | 50 | 68 | 11 |

| 15 | 25 | 10 | NBR/FKM | 50 | 68 | 12 |

| 15 | 25.5 | 7 | NBR/FKM | 50 | 70 | 7 |

| 15 | 26 | 4 | NBR/FKM | 50 | 70 | 8 |

| 15 | 26 | 5.5 | NBR/FKM | 50 | 70 | 9 |

| 15 | 26 | 6 | NBR/FKM | 50 | 70 | 10 |

| 15 | 26 | 6.5 | NBR/FKM | 50 | 70 | 12 |

| 15 | 26 | 7 | NBR/FKM | 50 | 72 | 5 |

| 15 | 27 | 5 | NBR/FKM | 50 | 72 | 6 |

| 15 | 27 | 7 | NBR/FKM | 50 | 72 | 7 |

| 15 | 27 | 8 | NBR/FKM | 50 | 72 | 8 |

| 15 | 28 | 8 | NBR/FKM | 50 | 72 | 9 |

| 15 | 28 | 4.5 | NBR/FKM | 50 | 72 | 10 |

| 15 | 28 | 5 | NBR/FKM | 50 | 72 | 12 |

| 15 | 28 | 6 | NBR/FKM | 50 | 72 | 14 |

| 15 | 28 | 7 | NBR/FKM | 50 | 73 | 9 |

| 15 | 28 | 8 | NBR/FKM | 50 | 73 | 10 |

| 15 | 28 | 10 | NBR/FKM | 50 | 73 | 12 |

| 15 | 29 | 7 | NBR/FKM | 50 | 75 | 7 |

| 15 | 30 | 4.5 | NBR/FKM | 50 | 75 | 8 |

| 15 | 30 | 5 | NBR/FKM | 50 | 75 | 10 |

| 15 | 30 | 6 | NBR/FKM | 50 | 75 | 12 |

| 15 | 30 | 7 | NBR/FKM | 50 | 76 | 10 |

| 15 | 30 | 8 | NBR/FKM | 50 | 76 | 12 |

| 15 | 30 | 10 | NBR/FKM | 50 | 76.5 | 13 |

| 15 | 31 | 7 | NBR/FKM | 50 | 78 | 8 |

| 15 | 32 | 7 | NBR/FKM | 50 | 78 | 10 |

| 15 | 32 | 7.5 | NBR/FKM | 50 | 78 | 12 |

| 15 | 32 | 9 | NBR/FKM | 50 | 80 | 8 |

| 15 | 32 | 10 | NBR/FKM | 50 | 80 | 10 |

| 15 | 33 | 7 | NBR/FKM | 50 | 80 | 12 |

| 15 | 33 | 9 | NBR/FKM | 50 | 80 | 13 |

| 15 | 34 | 7 | NBR/FKM | 50 | 81 | 10 |

| 15 | 35 | 4.5 | NBR/FKM | 50 | 82 | 8 |

| 15 | 35 | 5 | NBR/FKM | 50 | 82 | 10 |

| 15 | 35 | 5.3 | NBR/FKM | 50 | 82 | 12 |

| 15 | 35 | 6 | NBR/FKM | 50 | 85 | 8 |

| 15 | 35 | 7 | NBR/FKM | 50 | 85 | 10 |

| 15 | 35 | 8 | NBR/FKM | 50 | 85 | 12 |

| 15 | 35 | 10 | NBR/FKM | 50 | 90 | 8 |

| 15 | 36 | 7 | NBR/FKM | 50 | 90 | 10 |

| 15 | 37 | 7 | NBR/FKM | 50 | 90 | 12 |

| 15 | 38 | 7 | NBR/FKM | 50 | 90 | 13 |

| 15 | 38 | 10 | NBR/FKM | 50 | 91 | 9 |

| 15 | 40 | 7 | NBR/FKM | 50 | 92 | 8 |

| 15 | 40 | 8 | NBR/FKM | 50 | 92 | 10 |

| 15 | 40 | 9 | NBR/FKM | 50 | 95 | 10 |

| 15 | 40 | 10 | NBR/FKM | 50 | 100 | 8.5 |

| 15 | 42 | 7 | NBR/FKM | 50 | 100 | 10 |

| 15 | 42 | 8 | NBR/FKM | 50 | 100 | 12 |

| 15 | 42 | 10 | NBR/FKM | 50 | 110 | 10 |

| 15 | 47 | 7 | NBR/FKM | 51 | 57 | 3 |

| 15 | 48 | 8 | NBR/FKM | 51 | 63 | 6 |

| 15.5 | 25.5 | 7 | NBR/FKM | 51 | 63 | 7 |

| 16 | 21 | 6 | NBR/FKM | 51 | 63 | 9 |

| 16 | 22 | 4 | NBR/FKM | 51 | 65 | 6 |

| 16 | 22 | 6 | NBR/FKM | 51 | 66 | 7 |

| 16 | 22 | 7 | NBR/FKM | 51 | 70 | 9.5 |

| 16 | 22.75 | 4.5 | NBR/FKM | 51 | 70 | 10 |

| 16 | 24 | 4 | NBR/FKM | 51 | 70 | 12 |

| 16 | 24 | 5 | NBR/FKM | 51 | 76 | 13 |

| 16 | 24 | 6 | NBR/FKM | 52 | 60 | 7 |

| 16 | 24 | 7 | NBR/FKM | 52 | 62 | 7 |

| 16 | 25 | 4 | NBR/FKM | 52 | 62 | 8 |

| 16 | 25 | 5 | NBR/FKM | 52 | 62 | 9 |

| 16 | 25 | 6 | NBR/FKM | 52 | 62 | 10 |

| 16 | 25 | 7 | NBR/FKM | 52 | 63 | 6 |

| 16 | 26 | 5 | NBR/FKM | 52 | 63 | 8 |

| 16 | 26 | 6 | NBR/FKM | 52 | 63 | 9 |

| 16 | 26 | 7 | NBR/FKM | 52 | 64 | 9 |

| 16 | 26 | 7 | NBR/FKM | 52 | 65 | 7 |

| 16 | 26 | 9 | NBR/FKM | 52 | 65 | 8 |

| 16 | 27 | 7 | NBR/FKM | 52 | 65 | 9 |

| 16 | 28 | 6 | NBR/FKM | 52 | 65 | 10 |

| 16 | 28 | 7 | NBR/FKM | 52 | 65 | 13 |

| 16 | 28 | 8 | NBR/FKM | 52 | 66 | 8 |

| 16 | 29 | 7 | NBR/FKM | 52 | 66 | 10 |

| 16 | 30 | 4.5 | NBR/FKM | 52 | 67 | 6.7 |

| 16 | 30 | 5 | NBR/FKM | 52 | 68 | 7 |

| 16 | 30 | 6 | NBR/FKM | 52 | 68 | 8 |

| 16 | 30 | 7 | NBR/FKM | 52 | 68 | 9 |

| 16 | 30 | 7.5 | NBR/FKM | 52 | 68 | 10 |

| 16 | 30 | 8 | NBR/FKM | 52 | 68 | 13 |

| 16 | 40 | 10 | NBR/FKM | 52 | 69 | 10 |

| 16 | 31 | 7 | NBR/FKM | 52 | 70 | 8 |

| 16 | 32 | 7 | NBR/FKM | 52 | 70 | 9 |

| 16 | 32 | 8 | NBR/FKM | 52 | 70 | 10 |

| 16 | 32 | 10 | NBR/FKM | 52 | 70 | 12 |

| 16 | 33 | 4 | NBR/FKM | 52 | 70 | 13 |

| 16 | 33 | 7 | NBR/FKM | 52 | 72 | 7 |

| 16 | 34 | 7 | NBR/FKM | 52 | 72 | 8 |

| 16 | 35 | 6 | NBR/FKM | 52 | 72 | 9 |

| 16 | 35 | 7 | NBR/FKM | 52 | 72 | 10 |

| 16 | 35 | 8 | NBR/FKM | 52 | 72 | 12 |

| 16 | 35 | 10 | NBR/FKM | 52 | 73 | 10 |

| 16 | 36 | 7 | NBR/FKM | 52 | 74 | 12 |

| 16 | 36 | 8 | NBR/FKM | 52 | 75 | 8 |

| 16 | 37 | 7 | NBR/FKM | 52 | 75 | 10 |

| 16 | 38 | 7 | NBR/FKM | 52 | 75 | 12 |

| 16 | 38 | 8 | NBR/FKM | 52 | 76 | 9 |

| 16 | 40 | 7 | NBR/FKM | 52 | 78 | 8 |

| 16 | 40 | 8 | NBR/FKM | 52 | 78 | 10 |

| 16 | 40 | 10 | NBR/FKM | 52 | 80 | 8 |

| 16 | 47 | 10 | NBR/FKM | 52 | 80 | 10 |

| 17 | 23 | 10 | NBR/FKM | 52 | 80 | 12 |

| 17 | 24 | 5 | NBR/FKM | 52 | 80 | 13 |

| 17 | 24 | 7 | NBR/FKM | 52 | 84 | 12 |

| 17 | 25 | 4 | NBR/FKM | 52 | 85 | 9 |

| 17 | 25 | 5 | NBR/FKM | 52 | 85 | 10 |

| 17 | 25 | 6 | NBR/FKM | 52 | 85 | 12 |

| 17 | 25 | 7 | NBR/FKM | 52 | 85 | 13 |

| 17 | 25 | 10 | NBR/FKM | 52 | 90 | 10 |

| 17 | 26 | 5 | NBR/FKM | 52 | 92 | 13 |

| 17 | 26 | 6 | NBR/FKM | 52 | 100 | 15 |

| 17 | 26 | 7 | NBR/FKM | 53 | 68 | 7 |

| 17 | 27 | 4 | NBR/FKM | 53 | 68 | 9 |

| 17 | 27 | 6 | NBR/FKM | 53 | 70 | 9 |

| 17 | 27 | 7 | NBR/FKM | 53 | 71 | 9 |

| 17 | 27 | 8 | NBR/FKM | 53 | 72 | 10 |

| 17 | 27 | 10 | NBR/FKM | 53 | 73 | 7 |

| 17 | 28 | 5.5 | NBR/FKM | 53 | 73 | 10 |

| 17 | 28 | 6 | NBR/FKM | 54 | 64 | 8 |

| 17 | 28 | 6.5 | NBR/FKM | 54 | 64 | 9 |

| 17 | 28 | 7 | NBR/FKM | 54 | 65 | 8 |

| 17 | 28 | 8 | NBR/FKM | 54 | 65 | 10 |

| 17 | 28 | 9 | NBR/FKM | 54 | 65 | 13 |

| 17 | 28.5 | 7 | NBR/FKM | 54 | 68 | 8 |

| 17 | 29 | 5 | NBR/FKM | 54 | 68 | 9 |

| 17 | 29 | 6 | NBR/FKM | 54 | 68 | 10 |

| 17 | 29 | 7 | NBR/FKM | 54 | 70 | 6.7 |

| 17 | 29 | 8 | NBR/FKM | 54 | 70 | 7 |

| 17 | 30 | 5 | NBR/FKM | 54 | 70 | 8 |

| 17 | 30 | 6 | NBR/FKM | 54 | 70 | 9 |

| 17 | 30 | 7 | NBR/FKM | 54 | 70 | 10 |

| 17 | 30 | 8 | NBR/FKM | 54 | 70 | 12 |

| 17 | 30 | 10 | NBR/FKM | 54 | 72 | 8 |

| 17 | 31 | 5 | NBR/FKM | 54 | 72 | 10 |

| 17 | 31 | 7 | NBR/FKM | 54 | 73 | 8 |

| 17 | 32 | 5 | NBR/FKM | 54 | 73 | 10 |

| 17 | 32 | 6 | NBR/FKM | 54 | 74 | 10 |

| 17 | 32 | 7 | NBR/FKM | 54 | 75 | 8 |

| 17 | 32 | 8 | NBR/FKM | 54 | 75 | 10 |

| 17 | 32 | 9 | NBR/FKM | 54 | 75 | 12 |

| 17 | 32 | 10 | NBR/FKM | 54 | 75 | 12.5 |

| 17 | 33 | 7 | NBR/FKM | 54 | 76 | 8 |

| 17 | 34 | 4 | NBR/FKM | 54 | 76 | 12 |

| 17 | 34 | 6 | NBR/FKM | 54 | 77 | 10 |

| 17 | 34 | 7 | NBR/FKM | 54 | 80 | 10 |

| 17 | 34 | 8 | NBR/FKM | 54 | 80 | 12 |

| 17 | 35 | 5 | NBR/FKM | 54 | 80 | 13 |

| 17 | 35 | 6 | NBR/FKM | 54 | 81 | 10 |

| 17 | 35 | 7 | NBR/FKM | 54 | 81 | 12 |

| 17 | 35 | 8 | NBR/FKM | 54 | 82 | 10 |

| 17 | 35 | 10 | NBR/FKM | 54 | 82 | 11 |

| 17 | 36 | 7 | NBR/FKM | 54 | 85 | 8 |

| 17 | 37 | 7 | NBR/FKM | 54 | 85 | 10 |

| 17 | 37 | 9 | NBR/FKM | 54 | 85 | 12 |

| 17 | 37 | 10 | NBR/FKM | 54.8 | 70 | 9 |

| 17 | 38 | 7 | NBR/FKM | 55 | 65 | 7 |

| 17 | 38 | 8 | NBR/FKM | 55 | 65 | 8 |

| 17 | 38 | 10 | NBR/FKM | 55 | 65 | 10 |

| 17 | 40 | 6 | NBR/FKM | 55 | 65 | 12 |

| 17 | 40 | 7 | NBR/FKM | 55 | 68 | 6 |

| 17 | 40 | 8 | NBR/FKM | 55 | 68 | 8 |

| 17 | 40 | 10 | NBR/FKM | 55 | 68 | 8.5 |

| 17 | 42 | 7 | NBR/FKM | 55 | 68 | 10 |

| 17 | 42 | 8 | NBR/FKM | 55 | 68 | 12 |

| 17 | 43 | 9 | NBR/FKM | 55 | 70 | 7 |

| 17 | 45 | 7 | NBR/FKM | 55 | 70 | 8 |

| 17 | 46 | 6 | NBR/FKM | 55 | 70 | 9 |

| 17 | 47 | 7 | NBR/FKM | 55 | 70 | 10 |

| 17 | 47 | 8 | NBR/FKM | 55 | 70 | 12 |

| 17 | 47 | 10 | NBR/FKM | 55 | 72 | 6 |

| 17.46 | 28.58 | 6.9 | NBR/FKM | 55 | 72 | 7 |

| 17.5 | 28.6 | 6.9 | NBR/FKM | 55 | 72 | 8 |

| 17.5 | 32 | 7 | NBR/FKM | 55 | 72 | 9 |

| 18 | 24 | 4 | NBR/FKM | 55 | 72 | 10 |

| 18 | 24 | 5 | NBR/FKM | 55 | 72 | 12 |

| 18 | 24 | 7 | NBR/FKM | 55 | 73 | 7 |

| 18 | 25 | 7 | NBR/FKM | 55 | 73 | 10 |

| 18 | 26 | 4.5 | NBR/FKM | 55 | 75 | 6 |

| 18 | 26 | 5 | NBR/FKM | 55 | 75 | 7 |

| 18 | 26 | 7 | NBR/FKM | 55 | 75 | 8 |

| 18 | 27 | 7 | NBR/FKM | 55 | 75 | 9 |

| 18 | 28 | 6 | NBR/FKM | 55 | 75 | 10 |

| 18 | 28 | 7 | NBR/FKM | 55 | 75 | 12 |

| 18 | 28 | 10 | NBR/FKM | 55 | 76 | 10 |

| 18 | 29 | 7 | NBR/FKM | 55 | 76 | 12 |

| 18 | 30 | 5 | NBR/FKM | 55 | 77 | 10 |

| 18 | 30 | 6 | NBR/FKM | 55 | 78 | 8 |

| 18 | 30 | 7 | NBR/FKM | 55 | 78 | 9 |

| 18 | 30 | 8 | NBR/FKM | 55 | 78 | 10 |

| 18 | 30 | 10 | NBR/FKM | 55 | 78 | 12 |

| 18 | 31 | 7 | NBR/FKM | 55 | 80 | 8 |

| 18 | 32 | 6 | NBR/FKM | 55 | 80 | 10 |

| 18 | 32 | 7 | NBR/FKM | 55 | 80 | 12 |

| 18 | 32 | 8 | NBR/FKM | 55 | 80 | 13 |

| 18 | 32 | 8.5 | NBR/FKM | 55 | 81 | 10 |

| 18 | 32 | 10 | NBR/FKM | 55 | 82 | 9 |

| 18 | 34 | 7 | NBR/FKM | 55 | 82 | 10 |

| 18 | 34 | 8 | NBR/FKM | 55 | 82 | 12 |

| 18 | 35 | 7 | NBR/FKM | 55 | 82 | 13 |

| 18 | 35 | 8 | NBR/FKM | 55 | 85 | 8 |

| 18 | 35 | 10 | NBR/FKM | 55 | 85 | 10 |

| 18 | 36 | 7 | NBR/FKM | 55 | 85 | 12 |

| 18 | 36 | 10 | NBR/FKM | 55 | 85 | 13 |

| 18 | 37 | 7 | NBR/FKM | 55 | 88 | 10 |

| 18 | 37 | 8 | NBR/FKM | 55 | 90 | 8 |

| 18 | 38 | 7 | NBR/FKM | 55 | 90 | 10 |

| 18 | 38 | 10 | NBR/FKM | 55 | 90 | 12 |

| 18 | 39 | 7 | NBR/FKM | 55 | 90 | 13 |

| 18 | 40 | 7 | NBR/FKM | 55 | 92 | 9 |

| 18 | 40 | 8 | NBR/FKM | 55 | 95 | 10 |

| 18 | 40 | 10 | NBR/FKM | 55 | 95 | 12 |

| 18 | 40.5 | 5 | NBR/FKM | 55 | 100 | 8 |

| 18 | 42 | 7 | NBR/FKM | 55 | 100 | 10 |

| 18 | 42 | 10 | NBR/FKM | 55 | 100 | 12 |

| 18 | 47 | 8 | NBR/FKM | 55 | 100 | 13 |

| 18 | 47 | 10 | NBR/FKM | 55 | 101 | 4.7 |

| 18.5 | 35 | 7 | NBR/FKM | 55 | 110 | 8 |

| 18.9 | 28 | 5 | NBR/FKM | 55 | 110 | 10 |

| 18.9 | 30 | 5 | NBR/FKM | 55 | 110 | 12 |

| 19 | 25 | 6 | NBR/FKM | 56 | 66 | 11 |

| 19 | 25 | 8 | NBR/FKM | 56 | 66 | 17 |

| 19 | 26 | 7 | NBR/FKM | 56 | 68 | 8 |

| 19 | 27 | 5 | NBR/FKM | 56 | 70 | 9 |

| 19 | 27 | 6 | NBR/FKM | 56 | 72 | 7 |

| 19 | 27 | 7 | NBR/FKM | 56 | 72 | 8 |

| 19 | 27 | 10 | NBR/FKM | 56 | 72 | 9 |

| 19 | 28 | 7 | NBR/FKM | 56 | 72 | 10 |

| 19 | 29 | 7 | NBR/FKM | 56 | 73 | 7 |

| 19 | 30 | 6.5 | NBR/FKM | 56 | 73.15 | 10 |

| 19 | 30 | 7 | NBR/FKM | 56 | 75 | 8 |

| 19 | 30 | 8 | NBR/FKM | 56 | 76 | 6 |

| 19 | 30 | 10 | NBR/FKM | 56 | 76 | 6 |

| 19 | 31 | 7 | NBR/FKM | 56 | 80 | 8 |

| 19 | 32 | 4 | NBR/FKM | 56 | 80 | 10 |

| 19 | 32 | 5 | NBR/FKM | 56 | 80 | 13 |

| 19 | 32 | 6 | NBR/FKM | 56 | 85 | 8 |

| 19 | 32 | 7 | NBR/FKM | 56 | 85 | 10 |

| 19 | 32 | 8 | NBR/FKM | 56 | 86 | 12.9 |

| 19 | 32 | 8.5 | NBR/FKM | 56 | 88 | 8 |

| 19 | 32 | 10 | NBR/FKM | 56 | 90 | 8 |

| 19 | 33 | 7 | NBR/FKM | 56 | 90 | 10 |

| 19 | 33 | 8 | NBR/FKM | 57 | 67 | 6 |

| 19 | 34 | 7 | NBR/FKM | 57 | 71 | 7 |

| 19 | 34 | 8 | NBR/FKM | 57 | 71 | 8 |

| 19 | 35 | 5 | NBR/FKM | 57 | 72 | 12 |

| 19 | 35 | 6 | NBR/FKM | 57 | 73 | 7 |

| 19 | 35 | 7 | NBR/FKM | 57 | 75 | 12 |

| 19 | 35 | 8 | NBR/FKM | 57 | 76 | 10 |

| 19 | 35 | 10 | NBR/FKM | 57 | 76.3 | 12.5 |

| 19 | 35 | 10.3 | NBR/FKM | 57 | 79 | 10.5 |

| 19 | 36 | 6 | NBR/FKM | 57 | 80 | 10 |

| 19 | 36 | 6.5 | NBR/FKM | 57 | 80 | 12 |

| 19 | 36 | 7 | NBR/FKM | 57 | 85 | 10 |

| 19 | 37 | 7 | NBR/FKM | 57 | 85 | 12 |

| 19 | 37 | 10 | NBR/FKM | 57 | 90 | 10 |

| 19 | 38 | 7 | NBR/FKM | 57 | 92.2 | 12.7 |

| 19 | 38 | 8 | NBR/FKM | 57 | 124 | 10 |

| 19 | 38 | 10 | NBR/FKM | 57.15 | 76.2 | 12.7 |

| 19 | 40 | 7 | NBR/FKM | 57.2 | 76.2 | 12.7 |

| 19 | 40 | 10 | NBR/FKM | 57.5 | 85.75 | 12.7 |

| 19 | 41 | 7 | NBR/FKM | 58 | 68 | 9 |

| 19 | 42 | 7 | NBR/FKM | 58 | 70 | 8 |

| 19 | 42 | 7 | NBR/FKM | 58 | 70 | 9 |

| 19 | 42 | 8 | NBR/FKM | 58 | 70 | 10 |

| 19 | 45 | 7 | NBR/FKM | 58 | 70 | 11 |

| 19 | 45.5 | 7 | NBR/FKM | 58 | 70 | 12 |

| 19 | 47 | 7 | NBR/FKM | 58 | 72 | 8 |

| 19 | 47 | 8 | NBR/FKM | 58 | 72 | 9 |

| 19.4 | 31 | 7 | NBR/FKM | 58 | 72 | 10 |

| 19.5 | 35 | 10 | NBR/FKM | 58 | 72 | 12 |

| 19.8 | 30 | 5 | NBR/FKM | 58 | 74 | 10 |

| 19.8 | 30 | 7 | NBR/FKM | 58 | 75 | 7 |

| 20 | 25 | 7 | NBR/FKM | 58 | 75 | 8 |

| 20 | 25 | 8 | NBR/FKM | 58 | 75 | 9 |

| 20 | 26 | 4 | NBR/FKM | 58 | 75 | 10 |

| 20 | 26 | 5 | NBR/FKM | 58 | 75 | 11 |

| 20 | 27 | 5 | NBR/FKM | 58 | 75 | 12 |

| 20 | 28 | 6 | NBR/FKM | 58 | 75 | 7.5/11 |

| 20 | 28 | 7 | NBR/FKM | 58 | 76 | 10 |

| 20 | 28 | 8 | NBR/FKM | 58 | 76 | 11 |

| 20 | 28.5 | 5 | NBR/FKM | 58 | 76 | 12 |

| 20 | 28.6 | 5 | NBR/FKM | 58 | 78 | 8 |

| 20 | 30 | 4.5 | NBR/FKM | 58 | 78 | 10 |

| 20 | 30 | 5 | NBR/FKM | 58 | 78 | 12 |

| 20 | 30 | 6 | NBR/FKM | 58 | 79 | 9 |

| 20 | 30 | 7 | NBR/FKM | 58 | 80 | 8 |

| 20 | 30 | 8 | NBR/FKM | 58 | 80 | 9 |

| 20 | 30 | 9 | NBR/FKM | 58 | 80 | 10 |

| 20 | 30 | 10 | NBR/FKM | 58 | 80 | 12 |

| 20 | 31 | 7 | NBR/FKM | 58 | 80 | 13 |

| 20 | 32 | 5 | NBR/FKM | 58 | 82 | 10 |

| 20 | 32 | 6 | NBR/FKM | 58 | 82 | 12 |

| 20 | 32 | 7 | NBR/FKM | 58 | 82.5 | 11 |

| 20 | 32 | 7.5 | NBR/FKM | 58 | 85 | 8 |

| 20 | 32 | 8 | NBR/FKM | 58 | 85 | 9 |

| 20 | 32 | 10 | NBR/FKM | 58 | 85 | 10 |

| 20 | 33 | 7 | NBR/FKM | 58 | 85 | 12 |

| 20 | 33 | 10 | NBR/FKM | 58 | 86 | 12S |

| 20 | 33 | 12 | NBR/FKM | 58 | 89 | 10 |

| 20 | 34 | 7 | NBR/FKM | 58 | 90 | 10 |

| 20 | 35 | 4 | NBR/FKM | 58 | 9*0 | 12 |

| 20 | 35 | 5 | NBR/FKM | 58 | 90 | 13 |

| 20 | 35 | 5.5 | NBR/FKM | 58 | 92 | 8 |

| 20 | 35 | 6 | NBR/FKM | 58 | 103 | 12 |

| 20 | 35 | 7 | NBR/FKM | 59 | 72 | 12 |

| 20 | 35 | 8 | NBR/FKM | 59 | 75 | 10 |

| 20 | 35 | 9 | NBR/FKM | 59 | 86 | 13 |

| 20 | 35 | 10 | NBR/FKM | 60 | 70 | 8 |

| 20 | 35 | 12 | NBR/FKM | 60 | 70 | 10 |

| 20 | 36 | 6 | NBR/FKM | 60 | 70 | 12 |

| 20 | 36 | 7 | NBR/FKM | 60 | 72 | 8 |

| 20 | 36 | 8 | NBR/FKM | 60 | 72 | 9 |

| 20 | 36 | 10 | NBR/FKM | 60 | 72 | 10 |

| 20 | 37 | 6.5 | NBR/FKM | 60 | 72 | 12 |

| 20 | 37 | 7 | NBR/FKM | 60 | 74 | 8 |

| 20 | 37 | 8 | NBR/FKM | 60 | 74 | 10 |

| 20 | 37 | 10 | NBR/FKM | 60 | 75 | 7 |

| 20 | 38 | 5 | NBR/FKM | 60 | 75 | 8 |

| 20 | 38 | 7 | NBR/FKM | 60 | 75 | 9 |

| 20 | 38 | 8 | NBR/FKM | 60 | 75 | 10 |

| 20 | 38 | 10 | NBR/FKM | 60 | 75 | 12 |

| 20 | 39 | 6 | NBR/FKM | 60 | 76 | 8 |

| 20 | 40 | 4 | NBR/FKM | 60 | 76 | 9 |

| 20 | 40 | 5 | NBR/FKM | 60 | 77 | 10 |

| 20 | 40 | 6 | NBR/FKM | 60 | 77 | 12 |

| 20 | 40 | 6.5 | NBR/FKM | 60 | 78 | 7 |

| 20 | 40 | 7 | NBR/FKM | 60 | 78 | 8 |

| 20 | 40 | 8 | NBR/FKM | 60 | 78 | 9 |

| 20 | 40 | 10 | NBR/FKM | 60 | 78 | 10 |

| 20 | 40 | 12 | NBR/FKM | 60 | 78 | 13 |

| 20 | 40.6 | 11 | NBR/FKM | 60 | 80 | 7 |

| 20 | 41 | 7 | NBR/FKM | 60 | 80 | 8 |

| 20 | 41.25 | 7 | NBR/FKM | 60 | 80 | 9 |

| 20 | 41.3 | 7 | NBR/FKM | 60 | 80 | 10 |

| 20 | 42 | 6 | NBR/FKM | 60 | 80 | 12 |

| 20 | 42 | 7 | NBR/FKM | 60 | 80 | 13 |

| 20 | 42 | 8 | NBR/FKM | 60 | 82 | 7 |

| 20 | 42 | 10 | NBR/FKM | 60 | 82 | 8 |

| 20 | 42 | 12 | NBR/FKM | 60 | 82 | 9 |

| 20 | 44 | 7 | NBR/FKM | 60 | 82 | 10 |

| 20 | 45 | 7 | NBR/FKM | 60 | 82 | 12 |

| 20 | 45 | 8 | NBR/FKM | 60 | 84 | 10 |

| 20 | 45 | 10 | NBR/FKM | 60 | 85 | 7 |

| 20 | 45 | 12 | NBR/FKM | 60 | 85 | 8 |

| 20 | 46 | 7 | NBR/FKM | 60 | 85 | 9 |

| 20 | 46 | 8 | NBR/FKM | 60 | 85 | 10 |

| 20 | 47 | 7 | NBR/FKM | 60 | 85 | 12 |

| 20 | 47 | 8 | NBR/FKM | 60 | 85 | 13 |

| 20 | 47 | 10 | NBR/FKM | 60 | 86 | 10 |

| 20 | 47 | 12 | NBR/FKM | 60 | 86.5 | 10 |

| 20 | 48 | 7 | NBR/FKM | 60 | 89 | 10 |

| 20 | 48 | 10 | NBR/FKM | 60 | 90 | 8 |

| 20 | 49 | 7 | NBR/FKM | 60 | 90 | 10 |

| 20 | 49 | 8 | NBR/FKM | 60 | 90 | 11 |

| 20 | 50 | 7 | NBR/FKM | 60 | 90 | 12 |

| 20 | 50 | 8 | NBR/FKM | 60 | 90 | 13 |

| 20 | 50 | 9 | NBR/FKM | 60 | 92 | 10 |

| 20 | 50 | 10 | NBR/FKM | 60 | 92 | 12 |

| 20 | 52 | 7 | NBR/FKM | 60 | 94 | 10 |

| 20 | 52 | 8 | NBR/FKM | 60 | 95 | 8 |

| 20 | 52 | 9 | NBR/FKM | 60 | 95 | 10 |

| 20 | 52 | 10 | NBR/FKM | 60 | 95 | 11 |

| 20 | 52 | 12 | NBR/FKM | 60 | 95 | 12 |

| 20 | 60 | 10 | NBR/FKM | 60 | 95 | 13 |

| 20 | 62 | 6.5 | NBR/FKM | 60 | 96 | 12 |

| 20 | 68 | 14 | NBR/FKM | 60 | 100 | 10 |

| 21 | 32 | 5 | NBR/FKM | 60 | 100 | 12 |

| 21 | 32 | 5.5 | NBR/FKM | 60 | 100 | 13 |

| 21 | 32 | 7 | NBR/FKM | 60 | 110 | 10 |

| 21 | 33 | 7 | NBR/FKM | 60 | 110 | 12 |

| 21 | 35 | 7 | NBR/FKM | 60 | 110 | 13 |

| 21 | 35 | 10 | NBR/FKM | 62 | 70 | 12 |

| 21 | 36 | 7 | NBR/FKM | 62 | 72 | 7 |

| 21 | 37 | 5 | NBR/FKM | 62 | 75 | 7 |

| 21 | 37 | 7 | NBR/FKM | 62 | 75 | 10 |

| 21 | 40 | 6 | NBR/FKM | 62 | 75 | 12 |

| 21 | 40 | 7 | NBR/FKM | 62 | 76 | 11 |

| 21 | 40.5 | 7 | NBR/FKM | 62 | 77 | 9 |

| 21 | 45 | 7 | NBR/FKM | 62 | 78 | 8 |

| 22 | 27 | 12 | NBR/FKM | 62 | 78 | 10 |

| 22 | 28 | 4 | NBR/FKM | 62 | 78 | 12 |

| 22 | 28 | 7 | NBR/FKM | 62 | 80 | 8 |

| 22 | 30 | 5 | NBR/FKM | 62 | 80 | 10 |

| 22 | 30 | 7 | NBR/FKM | 62 | 80 | 12 |

| 22 | 31 | 5 | NBR/FKM | 62 | 80 | 13 |

| 22 | 31 | 7 | NBR/FKM | 62 | 82 | 10 |

| 22 | 32 | 5 | NBR/FKM | 62 | 82 | 12 |

| 22 | 32 | 5.5 | NBR/FKM | 62 | 83 | 10 |

| 22 | 32 | 6 | NBR/FKM | 62 | 85 | 8 |

| 22 | 32 | 7 | NBR/FKM | 62 | 85 | 10 |

| 22 | 33 | 7 | NBR/FKM | 62 | 85 | 12 |

| 22 | 33 | 10 | NBR/FKM | 62 | 85 | 13 |

| 22 | 34 | 5 | NBR/FKM | 62 | 86 | 10 |

| 22 | 34 | 6 | NBR/FKM | 62 | 88 | 12 |

| 22 | 34 | 7 | NBR/FKM | 62 | 90 | 10 |

| 22 | 34 | 8 | NBR/FKM | 62 | 90 | 12 |

| 22 | 34.5 | 6 | NBR/FKM | 62 | 90 | 13 |

| 22 | 35 | 5 | NBR/FKM | 62 | 93 | 6 |

| 22 | 35 | 6 | NBR/FKM | 62 | 93 | 9 |

| 22 | 35 | 7 | NBR/FKM | 62 | 93 | 12 |

| 22 | 35 | 8 | NBR/FKM | 62 | 93 | 13 |

| 22 | 35 | 10 | NBR/FKM | 62 | 93 | 16 |

| 22 | 36 | 5 | NBR/FKM | 62 | 95 | 10 |

| 22 | 36 | 6 | NBR/FKM | 62 | 95 | 12 |

| 22 | 36 | 7 | NBR/FKM | 62 | 100 | 10 |

| 22 | 36 | 10 | NBR/FKM | 62 | 100 | 12 |

| 22 | 37 | 5 | NBR/FKM | 62 | 110 | 10 |

| 22 | 37 | 6 | NBR/FKM | 62 | 110 | 13 |

| 22 | 37 | 7 | NBR/FKM | 63 | 80 | 9 |

| 22 | 37 | 8 | NBR/FKM | 63 | 80 | 10 |

| 22 | 38 | 5 | NBR/FKM | 63 | 80 | 11.5 |

| 22 | 38 | 6 | NBR/FKM | 63 | 80 | 12 |

| 22 | 38 | 7 | NBR/FKM | 63 | 83 | 9.5 |

| 22 | 38 | 8 | NBR/FKM | 63 | 83 | 10 |

| 22 | 38 | 10 | NBR/FKM | 63 | 85 | 10 |

| 22 | 39 | 6 | NBR/FKM | 63 | 85 | 12 |

| 22 | 39 | 7 | NBR/FKM | 63 | 88 | 10 |

| 22 | 39 | 9 | NBR/FKM | 63 | 88 | 12 |

| 22 | 40 | 7 | NBR/FKM | 63 | 90 | 10 |

| 22 | 40 | 8 | NBR/FKM | 63 | 90 | 12 |

| 22 | 40 | 10 | NBR/FKM | 63 | 90 | 13 |

| 22 | 40 | 12 | NBR/FKM | 63 | 92 | 10 |

| 22 | 40 | 16 | NBR/FKM | 63 | 93 | 12 |

| 22 | 41 | 5 | NBR/FKM | 63 | 100 | 10 |

| 22 | 41 | 7 | NBR/FKM | 63 | 100 | 13 |

| 22 | 41.25 | 6 | NBR/FKM | 64 | 80 | 8 |

| 22 | 41.25 | 7 | NBR/FKM | 64 | 80 | 10 |

| 22 | 41.3 | 7 | NBR/FKM | 64 | 80 | 12 |

| 22 | 42 | 5 | NBR/FKM | 64 | 80 | 13 |

| 22 | 42 | 7 | NBR/FKM | 64 | 84 | 11 |

| 22 | 42 | 8 | NBR/FKM | 64 | 85 | 10 |

| 22 | 42 | 10 | NBR/FKM | 64 | 85 | 12 |

| 22 | 42 | 11 | NBR/FKM | 64 | 89 | 13 |

| 22 | 42 | 12 | NBR/FKM | 64 | 89 | 13.2 |

| 22 | 43 | 8 | NBR/FKM | 64 | 90 | 13 |

| 22 | 44 | 6 | NBR/FKM | 64 | 92 | 12 |

| 22 | 44 | 7 | NBR/FKM | 64 | 93.3 | 9 |

| 22 | 44 | 8 | NBR/FKM | 64 | 95 | 10 |

| 22 | 44 | 9 | NBR/FKM | 64.3 | 78.6 | 6 |

| 22 | 45 | 7 | NBR/FKM | 65 | 75 | 8 |

| 22 | 45 | 8 | NBR/FKM | 65 | 75 | 10 |

| 22 | 45 | 10 | NBR/FKM | 65 | 75 | 12 |

| 22 | 46 | 8 | NBR/FKM | 65 | 78 | 10 |

| 22 | 47 | 7 | NBR/FKM | 65 | 78 | 12 |

| 22 | 47 | 8 | NBR/FKM | 65 | 79 | 7 |

| 22 | 47 | 10 | NBR/FKM | 65 | 80 | 7 |

| 22 | 47 | 12 | NBR/FKM | 65 | 80 | 8 |

| 22 | 48 | 7 | NBR/FKM | 65 | 80 | 10 |

| 22 | 48 | 10 | NBR/FKM | 65 | 80 | 12 |

| 22 | 48 | 11 | NBR/FKM | 65 | 81 | 7 |

| 22 | 50 | 7 | NBR/FKM | 65 | 82 | 9 |

| 22 | 50 | 8 | NBR/FKM | 65 | 82 | 10 |

| 22 | 50 | 10 | NBR/FKM | 65 | 82 | 12 |

| 22 | 50 | 12 | NBR/FKM | 65 | 83 | 13 |

| 22 | 52 | 7 | NBR/FKM | 65 | 84 | 9 |

| 22 | 52 | 8 | NBR/FKM | 65 | 84 | 10 |

| 22 | 52 | 10 | NBR/FKM | 65 | 85 | 8 |

| 22 | 55 | 7 | NBR/FKM | 65 | 85 | 10 |

| 22 | 56 | 7 | NBR/FKM | 65 | 85 | 12 |

| 23 | 32 | 7 | NBR/FKM | 65 | 85 | 13 |

| 23 | 34 | 8 | NBR/FKM | 65 | 88 | 8 |

| 23 | 35 | 5 | NBR/FKM | 65 | 88 | 10 |

| 23 | 35 | 6 | NBR/FKM | 65 | 88 | 12 |

| 23 | 35 | 7 | NBR/FKM | 65 | 88 | 13 |

| 23 | 35 | 8 | NBR/FKM | 65 | 90 | 8 |

| 23 | 36 | 6 | NBR/FKM | 65 | 90 | 10 |

| 23 | 36 | 7 | NBR/FKM | 65 | 90 | 12 |

| 23 | 36 | 10 | NBR/FKM | 65 | 90 | 13 |

| 23 | 37 | 7 | NBR/FKM | 65 | 90 | 15 |

| 23 | 37 | 9 | NBR/FKM | 65 | 92 | 10 |

| 23 | 38 | 6 | NBR/FKM | 65 | 92 | 11 |

| 23 | 38 | 7 | NBR/FKM | 65 | 92 | 12 |

| 23 | 38 | 8 | NBR/FKM | 65 | 92 | 13 |

| 23 | 38 | 9 | NBR/FKM | 65 | 95 | 8 |

| 23 | 38 | 10 | NBR/FKM | 65 | 95 | 10 |

| 23 | 39 | 8 | NBR/FKM | 65 | 95 | 12 |

| 23 | 40 | 6 | NBR/FKM | 65 | 95 | 13 |

| 23 | 40 | 8 | NBR/FKM | 65 | 95 | 14 |

| 23 | 40 | 10 | NBR/FKM | 65 | 100 | 7 |

| 23 | 42 | 7 | NBR/FKM | 65 | 100 | 8 |

| 23 | 42 | 8 | NBR/FKM | 65 | 100 | 10 |

| 23 | 42 | 10 | NBR/FKM | 65 | 100 | 12 |

| 23 | 43 | 8 | NBR/FKM | 65 | 100 | 13 |

| 23 | 43 | 10 | NBR/FKM | 65 | 105 | 10 |

| 23 | 45 | 8 | NBR/FKM | 65 | 105 | 12 |

| 23 | 47 | 7 | NBR/FKM | 65 | 110 | 10 |

| 23 | 47 | 8 | NBR/FKM | 65 | 110 | 12 |

| 23 | 47 | 10 | NBR/FKM | 65 | 110 | 13 |

| 23.5 | 40 | 7 | NBR/FKM | 65 | 115 | 12 |

| 24 | 31 | 4 | NBR/FKM | 65 | 115 | 13 |

| 24 | 32 | 4 | NBR/FKM | 65 | 120 | 12 |

| 24 | 32 | 7 | NBR/FKM | 65 | 120 | 13 |

| 24 | 33 | 7 | NBR/FKM | 65 | 120 | 15 |

| 24 | 34 | 5 | NBR/FKM | 65 | 140 | 14 |

| 24 | 34 | 6 | NBR/FKM | 66 | 80 | 9 |

| 24 | 34 | 7 | NBR/FKM | 66 | 86 | 9 |

| 24 | 34 | 8 | NBR/FKM | 66 | 89 | 9 |

| 24 | 34.5 | 11 | NBR/FKM | 66.04 | 95.27 | 14 |

| 24 | 35 | 5 | NBR/FKM | 66.5 | 89 | 13 |

| 24 | 35 | 6 | NBR/FKM | 66.67 | 89.3 | 10 |

| 24 | 35 | 7 | NBR/FKM | 67 | 82 | 7 |

| 24 | 35 | 8 | NBR/FKM | 67 | 88 | 9 |

| 24 | 35 | 10 | NBR/FKM | 68 | 80 | 8 |

| 24 | 36 | 7 | NBR/FKM | 68 | 80 | 8.5 |

| 24 | 36 | 8 | NBR/FKM | 68 | 80 | 10 |

| 24 | 37 | 7 | NBR/FKM | 68 | 80 | 12 |

| 24 | 38 | 5 | NBR/FKM | 68 | 82 | 7 |

| 24 | 38 | 7 | NBR/FKM | 68 | 82 | 8 |

| 24 | 38 | 8 | NBR/FKM | 68 | 82 | 10 |

| 24 | 38 | 10 | NBR/FKM | 68 | 83 | 10 |

| 24 | 40 | 7 | NBR/FKM | 68 | 85 | 10 |

| 24 | 40 | 7.4 | NBR/FKM | 68 | 85 | 12 |

| 24 | 40 | 7.5 | NBR/FKM | 68 | 85 | 13 |

| 24 | 40 | 8 | NBR/FKM | 68 | 86 | 8 |

| 24 | 40 | 8.5 | NBR/FKM | 68 | 88 | 8 |

| 24 | 40 | 10 | NBR/FKM | 68 | 88 | 10 |

| 24 | 40 | 10 | NBR/FKM | 68 | 90 | 8 |

| 24 | 41.25 | 7 | NBR/FKM | 68 | 90 | 10 |

| 24 | 42 | 7 | NBR/FKM | 68 | 90 | 12 |

| 24 | 42 | 8 | NBR/FKM | 68 | 90 | 13 |

| 24 | 42 | 10 | NBR/FKM | 68 | 92 | 10 |

| 24 | 43 | 6 | NBR/FKM | 68 | 92 | 12 |

| 24 | 43 | 7 | NBR/FKM | 68 | 95 | 8 |

| 24 | 43 | 8.5 | NBR/FKM | 68 | 95 | 10 |

| 24 | 44 | 7 | NBR/FKM | 68 | 95 | 12 |

| 24 | 45 | 6 | NBR/FKM | 68 | 95 | 13 |

| 24 | 45 | 7 | NBR/FKM | 68 | 98 | 10 |

| 24 | 45 | 8 | NBR/FKM | 68 | 99 | 14 |

| 24 | 45 | 10 | NBR/FKM | 68 | 100 | 10 |

| 24 | 45 | 11 | NBR/FKM | 68 | 100 | 12 |

| 24 | 46 | 8 | NBR/FKM | 68 | 100 | 13 |

| 24 | 46 | 10 | NBR/FKM | 68 | 110 | 12 |

| 24 | 47 | 7 | NBR/FKM | 68 | 110 | 13 |

| 24 | 47 | 10 | NBR/FKM | 69 | 85 | 10 |

| 24 | 48 | 7 | NBR/FKM | 69 | 89 | 13 |

| 24 | 48 | 8 | NBR/FKM | 69 | 92 | 12 |

| 24 | 49 | 8 | NBR/FKM | 69 | 92 | 14 |

| 24 | 49 | 12 | NBR/FKM | 69 | 95 | 10 |

| 24 | 50 | 8 | NBR/FKM | 70 | 80 | 6 |

| 24 | 50 | 10 | NBR/FKM | 70 | 80 | 7 |

| 24 | 50 | 12 | NBR/FKM | 70 | 80 | 8 |

| 24 | 52 | 7 | NBR/FKM | 70 | 80 | 10 |

| 24 | 52 | 8 | NBR/FKM | 70 | 80 | 12 |

| 24 | 52 | 10 | NBR/FKM | 70 | 82 | 10 |

| 24 | 52 | 12 | NBR/FKM | 70 | 82 | 12 |

| 24 | 54 | 8 | NBR/FKM | 70 | 85 | 8 |

| 24 | 60 | 10 | NBR/FKM | 70 | 85 | 10 |

| 24.5 | 42 | 7 | NBR/FKM | 70 | 85 | 12 |

| 25 | 31 | 5 | NBR/FKM | 70 | 87 | 7 |

| 25 | 32 | 4 | NBR/FKM | 70 | 87 | 8.5 |

| 25 | 32 | 5 | NBR/FKM | 70 | 87 | 10 |

| 25 | 32 | 7 | NBR/FKM | 70 | 88 | 9 |

| 25 | 33 | 6 | NBR/FKM | 70 | 88 | 10 |

| 25 | 33 | 7 | NBR/FKM | 70 | 88 | 12 |

| 25 | 33 | 10 | NBR/FKM | 70 | 90 | 7 |

| 25 | 33.5 | 7 | NBR/FKM | 70 | 90 | 8 |

| 25 | 34 | 5 | NBR/FKM | 70 | 90 | 10 |

| 25 | 34 | 7 | NBR/FKM | 70 | 90 | 12 |

| 25 | 35 | 5 | NBR/FKM | 70 | 90 | 13 |

| 25 | 35 | 6 | NBR/FKM | 70 | 92 | 8 |

| 25 | 35 | 7 | NBR/FKM | 70 | 92 | 9 |

| 25 | 35 | 8 | NBR/FKM | 70 | 92 | 10 |

| 25 | 35 | 9 | NBR/FKM | 70 | 92 | 12 |

| 25 | 35 | 10 | NBR/FKM | 70 | 92 | 14 |

| 25 | 35 | 6R | NBR/FKM | 70 | 92 | 16 |

| 25 | 36 | 6 | NBR/FKM | 70 | 94 | 10 |

| 25 | 36 | 7 | NBR/FKM | 70 | 95 | 5 |

| 25 | 36 | 8 | NBR/FKM | 70 | 95 | 8 |

| 25 | 36 | 10 | NBR/FKM | 70 | 95 | 10 |

| 25 | 37 | 5 | NBR/FKM | 70 | 95 | 12 |

| 25 | 37 | 6 | NBR/FKM | 70 | 95 | 13 |

| 25 | 37 | 7 | NBR/FKM | 70 | 96 | 11 |

| 25 | 37 | 8 | NBR/FKM | 70 | 96 | 13 |

| 25 | 37 | 10 | NBR/FKM | 70 | 100 | 10 |

| 25 | 38 | 5 | NBR/FKM | 70 | 100 | 12 |

| 25 | 38 | 6 | NBR/FKM | 70 | 100 | 13 |

| 25 | 38 | 7 | NBR/FKM | 70 | 100 | 14 |

| 25 | 38 | 8 | NBR/FKM | 70 | 102 | 12 |

| 25 | 38 | 10 | NBR/FKM | 70 | 105 | 10 |

| 25 | 39 | 8 | NBR/FKM | 70 | 105 | 12 |

| 25 | 40 | 3 | NBR/FKM | 70 | 105 | 13 |

| 25 | 40 | 5 | NBR/FKM | 70 | 105 | 14 |

| 25 | 40 | 6 | NBR/FKM | 70 | 110 | 8 |

| 25 | 40 | 7 | NBR/FKM | 70 | 110 | 10 |

| 25 | 40 | 8 | NBR/FKM | 70 | 110 | 12 |

| 25 | 40 | 9 | NBR/FKM | 70 | 110 | 13 |

| 25 | 40 | 10 | NBR/FKM | 70 | 112 | 13 |

| 25 | 40 | 12 | NBR/FKM | 70 | 112 | 14 |

| 25 | 41 | 6 | NBR/FKM | 70 | 115 | 12 |

| 25 | 41 | 7 | NBR/FKM | 70 | 115 | 13 |

| 25 | 41.25 | 6 | NBR/FKM | 70 | 115 | 15 |

| 25 | 41.25 | 7 | NBR/FKM | 70 | 120 | 13 |

| 25 | 41.28 | 7 | NBR/FKM | 70 | 120 | 15 |

| 25 | 41.3 | 6 | NBR/FKM | 70 | 125 | 12 |

| 25 | 41.3 | 7 | NBR/FKM | 70 | 125 | 13 |

| 25 | 41.5 | 7 | NBR/FKM | 70 | 135 | 7 |

| 25 | 42 | 7 | NBR/FKM | 70.3 | 92 | 8.5 |

| 25 | 42 | 8 | NBR/FKM | 72 | 82 | 10 |

| 25 | 42 | 10 | NBR/FKM | 72 | 85 | 10 |

| 25 | 42 | 12 | NBR/FKM | 72 | 88 | 8 |

| 25 | 43 | 6 | NBR/FKM | 72 | 90 | 8 |

| 25 | 43 | 7 | NBR/FKM | 72 | 90 | 10 |

| 25 | 43 | 8 | NBR/FKM | 72 | 92 | 9.5 |

| 25 | 43 | 10 | NBR/FKM | 72 | 92 | 12 |

| 25 | 44 | 12 | NBR/FKM | 72 | 94 | 10 |

| 25 | 44 | 7 | NBR/FKM | 72 | 94 | 12 |

| 25 | 44 | 8 | NBR/FKM | 72 | 95 | 10 |

| 25 | 44 | 10 | NBR/FKM | 72 | 95 | 12 |

| 25 | 44.5 | 6 | NBR/FKM | 72 | 95 | 13 |

| 25 | 44.5 | 6/9 | NBR/FKM | 72 | 96 | 9 |

| 25 | 44.6 | 6 | NBR/FKM | 72 | 96 | 10 |

| 25 | 45 | 7 | NBR/FKM | 72 | 100 | 10 |

| 25 | 45 | 8 | NBR/FKM | 72 | 100 | 12 |

| 25 | 45 | 9 | NBR/FKM | 72 | 100 | 13 |

| 25 | 45 | 10 | NBR/FKM | 72 | 105 | 12 |

| 25 | 45 | 12 | NBR/FKM | 72 | 105 | 13 |

| 25 | 46 | 7 | NBR/FKM | 73 | 90 | 7 |

| 25 | 46 | 10 | NBR/FKM | 73 | 90 | 7.5 |

| 25 | 47 | 5 | NBR/FKM | 73 | 90 | 8 |

| 25 | 47 | 7 | NBR/FKM | 73 | 95 | 7 |

| 25 | 47 | 8 | NBR/FKM | 73 | 97 | 12 |

| 25 | 47 | 10 | NBR/FKM | 73 | 98 | 12 |

| 25 | 47 | 12 | NBR/FKM | 73.03 | 90.5 | 12 |

| 25 | 48 | 7 | NBR/FKM | 74 | 90 | 10 |

| 25 | 48 | 8 | NBR/FKM | 74 | 94 | 10 |

| 25 | 48 | 10 | NBR/FKM | 74 | 95 | 7 |

| 25 | 49 | 10 | NBR/FKM | 74 | 95 | 8 |

| 25 | 49.7 | 10.5/15 | NBR/FKM | 74 | 95 | 12 |

| 25 | 50 | 7 | NBR/FKM | 74 | 95 | 13 |

| 25 | 50 | 8 | NBR/FKM | 74 | 100 | 12 |

| 25 | 50 | 10 | NBR/FKM | 74 | 100 | 13 |

| 25 | 50 | 12 | NBR/FKM | 74 | 102 | 10 |

| 25 | 50.55 | 10 | NBR/FKM | 74 | 102 | 15 |

| 25 | 51 | 10 | NBR/FKM | 75 | 85 | 10 |

| 25 | 52 | 6 | NBR/FKM | 75 | 90 | 8 |

| 25 | 52 | 7 | NBR/FKM | 75 | 90 | 10 |

| 25 | 52 | 8 | NBR/FKM | 75 | 90 | 12 |

| 25 | 52 | 10 | NBR/FKM | 75 | 90 | 13 |

| 25 | 52 | 11.5 | NBR/FKM | 75 | 92 | 10 |

| 25 | 52 | 12 | NBR/FKM | 75 | 92 | 12 |

| 25 | 52 | 10/14 | NBR/FKM | 75 | 93 | 9 |

| 25 | 53 | 10 | NBR/FKM | 75 | 94 | 10 |

| 25 | 54 | 8 | NBR/FKM | 75 | 95 | 8 |

| 25 | 54 | 10 | NBR/FKM | 75 | 95 | 10 |

| 25 | 55 | 8 | NBR/FKM | 75 | 95 | 12 |

| 25 | 55 | 10 | NBR/FKM | 75 | 95 | 13 |

| 25 | 55 | 12 | NBR/FKM | 75 | 96 | 5 |

| 25 | 56 | 12 | NBR/FKM | 75 | 100 | 7 |

| 25 | 58 | 10 | NBR/FKM | 75 | 100 | 8 |

| 25 | 60 | 10 | NBR/FKM | 75 | 100 | 8.5 |

| 25 | 62 | 7 | NBR/FKM | 75 | 100 | 10 |

| 25 | 62 | 8 | NBR/FKM | 75 | 100 | 12 |

| 25 | 62 | 10 | NBR/FKM | 75 | 100 | 13 |

| 25 | 62 | 12 | NBR/FKM | 75 | 102 | 12 |

| 25 | 65 | 10 | NBR/FKM | 75 | 105 | 10 |

| 25 | 66 | 8.5 | NBR/FKM | 75 | 105 | 12 |

| 25 | 68 | 10 | NBR/FKM | 75 | 105 | 13 |

| 25 | 70 | 10 | NBR/FKM | 75 | 105 | 15 |

| 25 | 72 | 7 | NBR/FKM | 75 | 110 | 10 |

| 25 | 72 | 8 | NBR/FKM | 75 | 110 | 12 |

| 25 | 72 | 10 | NBR/FKM | 75 | 110 | 13 |

| 25 | 80 | 10 | NBR/FKM | 75 | 115 | 9.5 |

| 25.25 | 41 | 7 | NBR/FKM | 75 | 115 | 10 |

| 25.7 | 40.8 | 7.7 | NBR/FKM | 75 | 115 | 12 |

| 26 | 34 | 7 | NBR/FKM | 75 | 115 | 13 |

| 26 | 35 | 6 | NBR/FKM | 75 | 118 | 12 |

| 26 | 35 | 7 | NBR/FKM | 75 | 120 | 10 |

| 26 | 36 | 5 | NBR/FKM | 75 | 120 | 12 |

| 26 | 36 | 7 | NBR/FKM | 75 | 120 | 13 |

| 26 | 37 | 7 | NBR/FKM | 75 | 121 | 13 |

| 26 | 37 | 8 | NBR/FKM | 75 | 125 | 12 |

| 26 | 37 | 10.5 | NBR/FKM | 76 | 93 | 10 |

| 26 | 38 | 5 | NBR/FKM | 76 | 98 | 12 |

| 26 | 38 | 7 | NBR/FKM | 76 | 105 | 12 |

| 26 | 38 | 8 | NBR/FKM | 77 | 93 | 10 |

| 26 | 40 | 5 | NBR/FKM | 77 | 100 | 11 |

| 26 | 40 | 6 | NBR/FKM | 78 | 90 | 10 |

| 26 | 40 | 7 | NBR/FKM | 78 | 90 | 13 |

| 26 | 40 | 8 | NBR/FKM | 78 | 92 | 10 |

| 26 | 40 | 10 | NBR/FKM | 78 | 95 | 8 |

| 26 | 42 | 7 | NBR/FKM | 78 | 100 | 10 |

| 26 | 42 | 8 | NBR/FKM | 78 | 100 | 13 |

| 26 | 42 | 10 | NBR/FKM | 78 | 105 | 12 |

| 26 | 43 | 8 | NBR/FKM | 78 | 110 | 13 |

| 26 | 43 | 9 | NBR/FKM | 78 | 115 | 10 |

| 26 | 44 | 7 | NBR/FKM | 78 | 115 | 12 |

| 26 | 44 | 8 | NBR/FKM | 78 | 115 | 13 |

| 26 | 45 | 7 | NBR/FKM | 78 | 125 | 10 |

| 26 | 45 | 8 | NBR/FKM | 78 | 162 | 16 |

| 26 | 45 | 10 | NBR/FKM | 78 | 162.4 | 16 |

| 26 | 47 | 6 | NBR/FKM | 79 | 95 | 11 |

| 26 | 47 | 7 | NBR/FKM | 79 | 110 | 10 |

| 26 | 47 | 8 | NBR/FKM | 80 | 90 | 5 |

| 26 | 47 | 10 | NBR/FKM | 80 | 95 | 8 |

| 26 | 47 | 11 | NBR/FKM | 80 | 95 | 10 |

| 26 | 47 | 12 | NBR/FKM | 80 | 95 | 12 |

| 26 | 48 | 7 | NBR/FKM | 80 | 96 | 9 |

| 26 | 48 | 10 | NBR/FKM | 80 | 96 | 10 |

| 26 | 50 | 7 | NBR/FKM | 80 | 96 | 12 |

| 26 | 50 | 8 | NBR/FKM | 80 | 98 | 10 |

| 26 | 50 | 10 | NBR/FKM | 80 | 100 | 7 |

| 26 | 52 | 7 | NBR/FKM | 80 | 100 | 8 |

| 26 | 52 | 8 | NBR/FKM | 80 | 100 | 8.5 |

| 26 | 52 | 12 | NBR/FKM | 80 | 100 | 10 |

| 26 | 57 | 8 | NBR/FKM | 80 | 100 | 12 |

| 26 | 62 | 9 | NBR/FKM | 80 | 100 | 13 |

| 26 | 72 | 10 | NBR/FKM | 80 | 100 | 15 |

| 27 | 35 | 7 | NBR/FKM | 80 | 105 | 10 |

| 27 | 36 | 6 | NBR/FKM | 80 | 105 | 12 |

| 27 | 36 | 7 | NBR/FKM | 80 | 105 | 13 |

| 27 | 36 | 10 | NBR/FKM | 80 | 105 | 14 |

| 27 | 37 | 6 | NBR/FKM | 80 | 108 | 10 |

| 27 | 37 | 7 | NBR/FKM | 80 | 110 | 10 |

| 27 | 37 | 8 | NBR/FKM | 80 | 110 | 12 |

| 27 | 37 | 9 | NBR/FKM | 80 | 110 | 13 |

| 27 | 37 | 10 | NBR/FKM | 80 | 110.05 | 12 |

| 27 | 37 | 10.5 | NBR/FKM | 80 | 113 | 12 |

| 27 | 37 | 10D | NBR/FKM | 80 | 115 | 10 |

| 27 | 38 | 6 | NBR/FKM | 80 | 115 | 12 |

| 27 | 38 | 7 | NBR/FKM | 80 | 115 | 13 |

| 27 | 38 | 8 | NBR/FKM | 80 | 118 | 12 |

| 27 | 38 | 10 | NBR/FKM | 80 | 120 | 10 |

| 27 | 39 | 10 | NBR/FKM | 80 | 120 | 12 |

| 27 | 39 | 10.5 | NBR/FKM | 80 | 120 | 13 |

| 27 | 40 | 5 | NBR/FKM | 80 | 125 | 10 |

| 27 | 40 | 6 | NBR/FKM | 80 | 125 | 12 |

| 27 | 40 | 7 | NBR/FKM | 80 | 125 | 13 |

| 27 | 40 | 8 | NBR/FKM | 80 | 130 | 12 |

| 27 | 40 | 10 | NBR/FKM | 80 | 132 | 15 |

| 27 | 40 | 12 | NBR/FKM | 80 | 140 | 12 |

| 27 | 41 | 7 | NBR/FKM | 82 | 95 | 10 |

| 27 | 41 | 8 | NBR/FKM | 82 | 98 | 9 |

| 27 | 41 | 10 | NBR/FKM | 82 | 100 | 10 |

| 27 | 42 | 7 | NBR/FKM | 82 | 105 | 10 |

| 27 | 42 | 10 | NBR/FKM | 82 | 105 | 12 |

| 27 | 43 | 7 | NBR/FKM | 82 | 105 | 13 |

| 27 | 43 | 8 | NBR/FKM | 82 | 115 | 13 |

| 27 | 43 | 9 | NBR/FKM | 83 | 100 | 9 |

| 27 | 43 | 10 | NBR/FKM | 83 | 110 | 13 |

| 27 | 44 | 7 | NBR/FKM | 83 | 118 | 9 |

| 27 | 44 | 8 | NBR/FKM | 84 | 100 | 10 |

| 27 | 44 | 9 | NBR/FKM | 84 | 104 | 9 |

| 27 | 45 | 7 | NBR/FKM | 84 | 104 | 10 |

| 27 | 45 | 8 | NBR/FKM | 84 | 104 | 11 |

| 27 | 45 | 9 | NBR/FKM | 84.15 | 111.3 | 12.7 |

| 27 | 47 | 6 | NBR/FKM | 85 | 100 | 9 |

| 27 | 47 | 7 | NBR/FKM | 85 | 100 | 10 |

| 27 | 47 | 8 | NBR/FKM | 85 | 100 | 12 |

| 27 | 47 | 10 | NBR/FKM | 85 | 100 | 13 |

| 27 | 48 | 8 | NBR/FKM | 85 | 103 | 8 |

| 27 | 48 | 9 | NBR/FKM | 85 | 103 | 10 |

| 27 | 49 | 8 | NBR/FKM | 85 | 105 | 8 |

| 27 | 49 | 10 | NBR/FKM | 85 | 105 | 9 |

| 27 | 50 | 10 | NBR/FKM | 85 | 105 | 10 |

| 27 | 52 | 7 | NBR/FKM | 85 | 105 | 12 |

| 27 | 52 | 8 | NBR/FKM | 85 | 105 | 13 |

| 27 | 53 | 7 | NBR/FKM | 85 | 110 | 10 |

| 27 | 56 | 7 | NBR/FKM | 85 | 110 | 12 |

| 27 | 62 | 8 | NBR/FKM | 85 | 110 | 13 |

| 27.9 | 70 | 10 | NBR/FKM | 85 | 115 | 12 |

| 28 | 35 | 5 | NBR/FKM | 85 | 115 | 13 |

| 28 | 35 | 6 | NBR/FKM | 85 | 115 | 15 |

| 28 | 35 | 7 | NBR/FKM | 85 | 120 | 10 |

| 28 | 35 | 8 | NBR/FKM | 85 | 120 | 12 |

| 28 | 35 | 9 | NBR/FKM | 85 | 120 | 13 |

| 28 | 36 | 7 | NBR/FKM | 85 | 125 | 12 |

| 28 | 37 | 4 | NBR/FKM | 85 | 125 | 13 |

| 28 | 37 | 6 | NBR/FKM | 85 | 125 | 14 |

| 28 | 37 | 7 | NBR/FKM | 85 | 127 | 13 |

| 28 | 37 | 8 | NBR/FKM | 85 | 130 | 12 |

| 28 | 38 | 5 | NBR/FKM | 85 | 130 | 13 |

| 28 | 38 | 5.5 | NBR/FKM | 85 | 132 | 10 |

| 28 | 38 | 6 | NBR/FKM | 85 | 140 | 12 |

| 28 | 38 | 6.2 | NBR/FKM | 85 | 140 | 13 |

| 28 | 38 | 7 | NBR/FKM | 85 | 150 | 14 |

| 28 | 38 | 8 | NBR/FKM | 86 | 100 | 10 |

| 28 | 38 | 10 | NBR/FKM | 86 | 103 | 8 |

| 28 | 39 | 7 | NBR/FKM | 86 | 103 | 9 |

| 28 | 40 | 5 | NBR/FKM | 87 | 114 | 13 |

| 28 | 40 | 7 | NBR/FKM | 87 | 114.3 | 13 |

| 28 | 40 | 8 | NBR/FKM | 87 | 114.7 | 13 |

| 28 | 40 | 9 | NBR/FKM | 87 | 115 | 13 |

| 28 | 40 | 10 | NBR/FKM | 88 | 104 | 10 |

| 28 | 40.5 | 8 | NBR/FKM | 88 | 106 | 8 |

| 28 | 40.8 | 8 | NBR/FKM | 88 | 106 | 8.5 |

| 28 | 41 | 7 | NBR/FKM | 88 | 106 | 10 |

| 28 | 41 | 8 | NBR/FKM | 88 | 108 | 11 |

| 28 | 41.5 | 8 | NBR/FKM | 88 | 110 | 12 |

| 28 | 42 | 7 | NBR/FKM | 88 | 110 | 13 |

| 28 | 42 | 8 | NBR/FKM | 88 | 115 | 13 |

| 28 | 42 | 10 | NBR/FKM | 89 | 109 | 9 |

| 28 | 42 | 11 | NBR/FKM | 90 | 100 | 7 |

| 28 | 43 | 7 | NBR/FKM | 90 | 100 | 10 |

| 28 | 43 | 8 | NBR/FKM | 90 | 100 | 12 |

| 28 | 43 | 10 | NBR/FKM | 90 | 104 | 10 |

| 28 | 44 | 6 | NBR/FKM | 90 | 105 | 10 |

| 28 | 44 | 7 | NBR/FKM | 90 | 105 | 12 |

| 28 | 44 | 8 | NBR/FKM | 90 | 105 | 13 |

| 28 | 45 | 5 | NBR/FKM | 90 | 109 | 9 |

| 28 | 45 | 7 | NBR/FKM | 90 | 110 | 7 |

| 28 | 45 | 8 | NBR/FKM | 90 | 110 | 8 |

| 28 | 45 | 10 | NBR/FKM | 90 | 110 | 9 |

| 28 | 46 | 7 | NBR/FKM | 90 | 110 | 10 |

| 28 | 47 | 7 | NBR/FKM | 90 | 110 | 12 |

| 28 | 47 | 8 | NBR/FKM | 90 | 110 | 13 |

| 28 | 47 | 10 | NBR/FKM | 90 | 110 | 14 |

| 28 | 47 | 11 | NBR/FKM | 90 | 112 | 12 |

| 28 | 48 | 7 | NBR/FKM | 90 | 115 | 8 |

| 28 | 48 | 8 | NBR/FKM | 90 | 115 | 10 |

| 28 | 48 | 10 | NBR/FKM | 90 | 115 | 12 |

| 28 | 48 | 11 | NBR/FKM | 90 | 115 | 13 |

| 28 | 49 | 8 | NBR/FKM | 90 | 118 | 11.3 |

| 28 | 50 | 7 | NBR/FKM | 90 | 118 | 12 |

| 28 | 50 | 8 | NBR/FKM | 90 | 120 | 10 |

| 28 | 50 | 10 | NBR/FKM | 90 | 120 | 12 |

| 28 | 51 | 10 | NBR/FKM | 90 | 120 | 13 |

| 28 | 52 | 5 | NBR/FKM | 90 | 120 | 14 |

| 28 | 52 | 7 | NBR/FKM | 90 | 120 | 15 |

| 28 | 52 | 8 | NBR/FKM | 90 | 120 | 20 |

| 28 | 52 | 10 | NBR/FKM | 90 | 125 | 10 |

| 28 | 55 | 8 | NBR/FKM | 90 | 125 | 12 |

| 28 | 55 | 10 | NBR/FKM | 90 | 125 | 13 |

| 28 | 56 | 7 | NBR/FKM | 90 | 125 | 15 |

| 28 | 56 | 8 | NBR/FKM | 90 | 125.25 | 10 |

| 28 | 56 | 9 | NBR/FKM | 90 | 127 | 13 |

| 28 | 56 | 10 | NBR/FKM | 90 | 130 | 10 |

| 28 | 57 | 7 | NBR/FKM | 90 | 130 | 12 |

| 28 | 58 | 6 | NBR/FKM | 90 | 130 | 13 |

| 28 | 58 | 7 | NBR/FKM | 90 | 135 | 12 |

| 28 | 58 | 10 | NBR/FKM | 90 | 135 | 13 |

| 28 | 62 | 9 | NBR/FKM | 90 | 135 | 15 |

| 28 | 62 | 10 | NBR/FKM | 90 | 140 | 12 |

| 28 | 70 | 10 | NBR/FKM | 90 | 140 | 13 |

| 28.575 | 44.45 | 9.525 | NBR/FKM | 90 | 150 | 12 |

| 28.6 | 40 | 8 | NBR/FKM | 90 | 180 | 12 |

| 29 | 36 | 8 | NBR/FKM | 91 | 111 | 9 |

| 29 | 37 | 10 | NBR/FKM | 92 | 100 | 10 |

| 29 | 38 | 6 | NBR/FKM | 92 | 105 | 10 |

| 29 | 40 | 7 | NBR/FKM | 92 | 105 | 13 |

| 29 | 40 | 8 | NBR/FKM | 92 | 108 | 9.5 |

| 29 | 40 | 10 | NBR/FKM | 92 | 110 | 10 |

| 29 | 41 | 9 | NBR/FKM | 92 | 120 | 12 |

| 29 | 42 | 7 | NBR/FKM | 93 | 114 | 13 |

| 29 | 42 | 10 | NBR/FKM | 94 | 111.5 | 9.5 |

| 29 | 43 | 7 | NBR/FKM | 94 | 112 | 9.5 |

| 29 | 43 | 8 | NBR/FKM | 95 | 100 | 10 |

| 29 | 43 | 10 | NBR/FKM | 95 | 105 | 10 |

| 29 | 43 | 10.5 | NBR/FKM | 95 | 105 | 13 |

| 29 | 44 | 7 | NBR/FKM | 95 | 110 | 10 |

| 29 | 44 | 8 | NBR/FKM | 95 | 110 | 11 |

| 29 | 45 | 8 | NBR/FKM | 95 | 110 | 12 |

| 29 | 45 | 9 | NBR/FKM | 95 | 110 | 13 |

| 29 | 46 | 7 | NBR/FKM | 95 | 112 | 12 |

| 29 | 46 | 8 | NBR/FKM | 95 | 115 | 9.5 |

| 29 | 46 | 10 | NBR/FKM | 95 | 115 | 12 |

| 29 | 47 | 7 | NBR/FKM | 95 | 115 | 13 |

| 29 | 47 | 8 | NBR/FKM | 95 | 118 | 10 |

| 29 | 47 | 10 | NBR/FKM | 95 | 118 | 10.5 |

| 29 | 48 | 8 | NBR/FKM | 95 | 120 | 8 |

| 29 | 48 | 10 | NBR/FKM | 95 | 120 | 10 |

| 29 | 49 | 8 | NBR/FKM | 95 | 120 | 12 |

| 29 | 50 | 7 | NBR/FKM | 95 | 120 | 13 |

| 29 | 50 | 8 | NBR/FKM | 95 | 120 | 14 |

| 29 | 50 | 10 | NBR/FKM | 95 | 125 | 10 |

| 29 | 52 | 7 | NBR/FKM | 95 | 125 | 12 |

| 29 | 54 | 9 | NBR/FKM | 95 | 130 | 10 |

| 29 | 54 | 10 | NBR/FKM | 95 | 130 | 12 |

| 29 | 56 | 10 | NBR/FKM | 95 | 130 | 13 |

| 29.5 | 40 | 10 | NBR/FKM | 95 | 135 | 10 |

| 30 | 37 | 4 | NBR/FKM | 95 | 135 | 12 |

| 30 | 37 | 8 | NBR/FKM | 95 | 135 | 13 |

| 30 | 38 | 4 | NBR/FKM | 95 | 140 | 12 |

| 30 | 38 | 5 | NBR/FKM | 95 | 140 | 13 |

| 30 | 38 | 6 | NBR/FKM | 95 | 145 | 10 |

| 30 | 38 | 8 | NBR/FKM | 95 | 170 | 13 |

| 30 | 38 | 10 | NBR/FKM | 96 | 115 | 12 |

| 30 | 40 | 5 | NBR/FKM | 96 | 120 | 12 |

| 30 | 40 | 6 | NBR/FKM | 98 | 116 | 10 |

| 30 | 40 | 7 | NBR/FKM | 98 | 120 | 12 |

| 30 | 40 | 8 | NBR/FKM | 98 | 120 | 13 |

| 30 | 40 | 10 | NBR/FKM | 98 | 127 | 12 |

| 30 | 40 | 12 | NBR/FKM | 98 | 130 | 12 |

| 30 | 40 | 7S | NBR/FKM | 98 | 130 | 13 |

| 30 | 40.5 | 10.5 | NBR/FKM | 100 | 110 | 12 |

| 30 | 41 | 5 | NBR/FKM | 100 | 114 | 7 |

| 30 | 41 | 7 | NBR/FKM | 100 | 115 | 9 |

| 30 | 41 | 10 | NBR/FKM | 100 | 115 | 10 |

| 30 | 41 | 10.5 | NBR/FKM | 100 | 115 | 12 |

| 30 | 42 | 4.5 | NBR/FKM | 100 | 115 | 13 |

| 30 | 42 | 5 | NBR/FKM | 100 | 118 | 10 |

| 30 | 42 | 6 | NBR/FKM | 100 | 118 | 12 |

| 30 | 42 | 7 | NBR/FKM | 100 | 120 | 8 |

| 30 | 42 | 8 | NBR/FKM | 100 | 120 | 10 |

| 30 | 42 | 9 | NBR/FKM | 100 | 120 | 11 |

| 30 | 42 | 10 | NBR/FKM | 100 | 120 | 12 |

| 30 | 42 | 10.5 | NBR/FKM | 100 | 120 | 13 |

| 30 | 42 | 11 | NBR/FKM | 100 | 124 | 13 |

| 30 | 43 | 7 | NBR/FKM | 100 | 125 | 10 |

| 30 | 43 | 8 | NBR/FKM | 100 | 125 | 12 |

| 30 | 43 | 8.5 | NBR/FKM | 100 | 125 | 13 |

| 30 | 43 | 9 | NBR/FKM | 100 | 125 | 15 |

| 30 | 43 | 10 | NBR/FKM | 100 | 130 | 10 |

| 30 | 43.5 | 7 | NBR/FKM | 100 | 130 | 12 |

| 30 | 44 | 7 | NBR/FKM | 100 | 130 | 13 |

| 30 | 44 | 8 | NBR/FKM | 100 | 130 | 14 |

| 30 | 44 | 9 | NBR/FKM | 100 | 130 | 15 |

| 30 | 44 | 10 | NBR/FKM | 100 | 130 | 16 |

| 30 | 44 | 10.5 | NBR/FKM | 100 | 135 | 10 |

| 30 | 45 | 6 | NBR/FKM | 100 | 135 | 12 |

| 30 | 45 | 7 | NBR/FKM | 100 | 135 | 13 |

| 30 | 45 | 8 | NBR/FKM | 100 | 135 | 14 |

| 30 | 45 | 10 | NBR/FKM | 100 | 135 | 15 |

| 30 | 45 | 12 | NBR/FKM | 100 | 140 | 12 |

| 30 | 46 | 6 | NBR/FKM | 100 | 140 | 13 |

| 30 | 46 | 7 | NBR/FKM | 100 | 140 | 14 |

| 30 | 46 | 8 | NBR/FKM | 100 | 145 | 14 |

| 30 | 46 | 10 | NBR/FKM | 100 | 145 | 15 |

| 30 | 47 | 5 | NBR/FKM | 100 | 150 | 10 |

| 30 | 47 | 6 | NBR/FKM | 100 | 150 | 12 |

| 30 | 47 | 7 | NBR/FKM | 100 | 150 | 13 |

| 30 | 47 | 8 | NBR/FKM | 100 | 150 | 14 |

| 30 | 47 | 10 | NBR/FKM | 100 | 150 | 15 |

| 30 | 48 | 7 | NBR/FKM | 100 | 155 | 12 |

| 30 | 48 | 8 | NBR/FKM | 100 | 155 | 14 |

| 30 | 48 | 10 | NBR/FKM | 100 | 155 | 16 |

| 30 | 48 | 12 | NBR/FKM | 100 | 160 | 14 |

| 30 | 49 | 7 | NBR/FKM | 100 | 200 | 15 |

| 30 | 49 | 8 | NBR/FKM | 101 | 114 | 10 |

| 30 | 49 | 10 | NBR/FKM | 101 | 130 | 13 |

| 30 | 50 | 7 | NBR/FKM | 102 | 125 | 13 |

| 30 | 50 | 8 | NBR/FKM | 102 | 130 | 13 |

| 30 | 50 | 10 | NBR/FKM | 105 | 110 | 14 |

| 30 | 50 | 11 | NBR/FKM | 105 | 120 | 8 |

| 30 | 50 | 12 | NBR/FKM | 105 | 120 | 10 |

| 30 | 51 | 7 | NBR/FKM | 105 | 120 | 11 |

| 30 | 51 | 10 | NBR/FKM | 105 | 120 | 12 |

| 30 | 52 | 7 | NBR/FKM | 105 | 120 | 13 |

| 30 | 52 | 8 | NBR/FKM | 105 | 125 | 10 |

| 30 | 52 | 10 | NBR/FKM | 105 | 125 | 12 |

| 30 | 52 | 11 | NBR/FKM | 105 | 125 | 13 |

| 30 | 52 | 12 | NBR/FKM | 105 | 126 | 13 |

| 30 | 53.3 | 10/14 | NBR/FKM | 105 | 130 | 12 |

| 30 | 54 | 6 | NBR/FKM | 105 | 130 | 13 |

| 30 | 54 | 7 | NBR/FKM | 105 | 130 | 14 |

| 30 | 54 | 9 | NBR/FKM | 105 | 130 | 15 |

| 30 | 54 | 10 | NBR/FKM | 105 | 130 | 18 |

| 30 | 55 | 5 | NBR/FKM | 105 | 135 | 9 |

| 30 | 55 | 7 | NBR/FKM | 105 | 135 | 12 |

| 30 | 55 | 8 | NBR/FKM | 105 | 135 | 13 |

| 30 | 55 | 9 | NBR/FKM | 105 | 135 | 14 |

| 30 | 55 | 10 | NBR/FKM | 105 | 138 | 12 |

| 30 | 55 | 11 | NBR/FKM | 105 | 140 | 12 |

| 30 | 55 | 12 | NBR/FKM | 105 | 140 | 13 |

| 30 | 55 | 23 | NBR/FKM | 105 | 140 | 14 |

| 30 | 56 | 7 | NBR/FKM | 105 | 140 | 15 |

| 30 | 56 | 8 | NBR/FKM | 105 | 145 | 12 |

| 30 | 56 | 10 | NBR/FKM | 105 | 145 | 14 |

| 30 | 56 | 12 | NBR/FKM | 105 | 145 | 15 |

| 30 | 57 | 10 | NBR/FKM | 105 | 150 | 14 |

| 30 | 57.5 | 10 | NBR/FKM | 105 | 150 | 15 |

| 30 | 58 | 8 | NBR/FKM | 105 | 155 | 14 |

| 30 | 58 | 9 | NBR/FKM | 106 | 126 | 12 |

| 30 | 58 | 10 | NBR/FKM | 107 | 127 | 13 |

| 30 | 58 | 12 | NBR/FKM | 108 | 125 | 7 |

| 30 | 60 | 7 | NBR/FKM | 108 | 140 | 14 |

| 30 | 60 | 8 | NBR/FKM | 108 | 180 | 17 |

| 30 | 60 | 10 | NBR/FKM | 110 | 125 | 10 |

| 30 | 60 | 12 | NBR/FKM | 110 | 125 | 12 |

| 30 | 62 | 7 | NBR/FKM | 110 | 125 | 13 |

| 30 | 62 | 8 | NBR/FKM | 110 | 130 | 8 |

| 30 | 62 | 10 | NBR/FKM | 110 | 130 | 10 |

| 30 | 62 | 11 | NBR/FKM | 110 | 130 | 12 |

| 30 | 62 | 12 | NBR/FKM | 110 | 130 | 13 |

| 30 | 65 | 8 | NBR/FKM | 110 | 130 | 14 |

| 30 | 65 | 10 | NBR/FKM | 110 | 130 | 15 |

| 30 | 65 | 12 | NBR/FKM | 110 | 132 | 7 |

| 30 | 66 | 10 | NBR/FKM | 110 | 135 | 9 |

| 30 | 68 | 6 | NBR/FKM | 110 | 135 | 10 |

| 30 | 68 | 10 | NBR/FKM | 110 | 135 | 12 |

| 30 | 68 | 12 | NBR/FKM | 110 | 135 | 13 |

| 30 | 70 | 10 | NBR/FKM | 110 | 135 | 14 |

| 30 | 70 | 11 | NBR/FKM | 110 | 138 | 12 |

| 30 | 70 | 12 | NBR/FKM | 110 | 140 | 12 |

| 30 | 72 | 7 | NBR/FKM | 110 | 140 | 13 |

| 30 | 72 | 8 | NBR/FKM | 110 | 140 | 14 |

| 30 | 72 | 9 | NBR/FKM | 110 | 140 | 15 |

| 30 | 72 | 10 | NBR/FKM | 110 | 142 | 12 |

| 30 | 72 | 11 | NBR/FKM | 110 | 142 | 14 |

| 30 | 72 | 12 | NBR/FKM | 110 | 145 | 12 |

| 30 | 75 | 9 | NBR/FKM | 110 | 145 | 13 |

| 30 | 75 | 10 | NBR/FKM | 110 | 145 | 15 |

| 30 | 77 | 9 | NBR/FKM | 110 | 146 | 14 |

| 30 | 77 | 10 | NBR/FKM | 110 | 146 | 15 |

| 30 | 80 | 10 | NBR/FKM | 110 | 150 | 13 |

| 31 | 39 | 8 | NBR/FKM | 110 | 150 | 14 |

| 31 | 40 | 7 | NBR/FKM | 110 | 154 | 34 |

| 31 | 42 | 8 | NBR/FKM | 110 | 160 | 12 |

| 31 | 43 | 10 | NBR/FKM | 110 | 160 | 13 |

| 31 | 43 | 12.5 | NBR/FKM | 110 | 160 | 14 |

| 31 | 44 | 10 | NBR/FKM | 110 | 170 | 13 |

| 31 | 45 | 7 | NBR/FKM | 110 | 170 | 15 |

| 31 | 46 | 10 | NBR/FKM | 110 | 200 | 12 |

| 31 | 47 | 8 | NBR/FKM | 112 | 140 | 13 |

| 31 | 47 | 10 | NBR/FKM | 112 | 140 | 14 |

| 31 | 48 | 10 | NBR/FKM | 114 | 135 | 13 |

| 31 | 49 | 7 | NBR/FKM | 114 | 145 | 14 |

| 31 | 50 | 8 | NBR/FKM | 115 | 130 | 12 |

| 31 | 51 | 9 | NBR/FKM | 115 | 130 | 14 |

| 31 | 52 | 6 | NBR/FKM | 115 | 135 | 13 |

| 31 | 52 | 7 | NBR/FKM | 115 | 135 | 14 |

| 31 | 57 | 7 | NBR/FKM | 115 | 140 | 12 |

| 31 | 68 | 8 | NBR/FKM | 115 | 140 | 13 |

| 31.5 | 44.45 | 9.7 | NBR/FKM | 115 | 140 | 14 |

| 31.7 | 41.2 | 6.35 | NBR/FKM | 115 | 140 | 15 |

| 31.75 | 44.45 | 6.35 | NBR/FKM | 115 | 140 | 16 |

| 31.75 | 44.45 | 9.53 | NBR/FKM | 115 | 145 | 13 |

| 31.75 | 50.8 | 9.52S | NBR/FKM | 115 | 145 | 14 |

| 32 | 38 | 5 | NBR/FKM | 115 | 145 | 15 |

| 32 | 38.5 | 8 | NBR/FKM | 115 | 145 | 16 |

| 32 | 39 | 7 | NBR/FKM | 115 | 150 | 12 |

| 32 | 40 | 5 | NBR/FKM | 115 | 150 | 14 |